Palladium water recovery: palladium wastewater recovery methods, processes, and precautions

Palladium water is wastewater containing palladium elements, usually generated from the production process of palladium salts or reactions using palladium catalysts. Due to palladium being a rare and

Palladium water is wastewater containing palladium elements, usually generated from the production process of palladium salts or reactions using palladium catalysts. Due to palladium being a rare and expensive precious metal, the recovery and reuse of waste palladium water has important economic and environmental significance. This article will introduce the methods and processes used in the centralized recovery of waste palladium water, and introduce the precautions during the recovery process.

1、 Palladium water recovery method and process

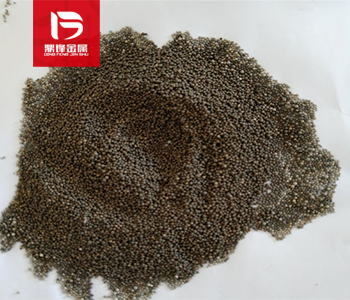

1. Precipitation method: Precipitation method is a method of precipitating palladium from an aqueous solution. Chemical precipitants such as ammonium chloride or sodium chloride can be used to convert palladium into insoluble precipitates. Then, pure palladium precipitate is obtained through steps such as filtration, washing, and drying.

2. Ion exchange method: The ion exchange method is a method of using ion exchange resins to adsorb and desorb palladium ions from aqueous solutions. Firstly, the palladium aqueous solution is passed through an ion exchange resin column, where palladium ions are adsorbed by the resin. Then, an appropriate solution is used to elute to obtain a solution containing high concentrations of palladium ions. Finally, palladium ions are reduced to metallic palladium by heating or electrolysis.

3. Electrolysis method: Electrolysis method uses palladium aqueous solution as an electrolyte, and through the action of an external current in the electrolysis tank, palladium ions are reduced to metallic palladium at the cathode. At the same time, an oxidation reaction occurs on the anode, which oxidizes the impurities in the waste palladium water. By controlling parameters such as current density, electrolysis time, and electrolysis conditions, high-purity palladium metal can be obtained.

4. Electrodialysis method: Electrodialysis method uses the electric field force and the movement property of electrolyte to move palladium ions from the aqueous solution to the cathode through electrolysis in the electrolytic cell to form pure palladium deposition. The Electrodialysis method has the advantages of low energy consumption and simple operation, and is suitable for the recovery of low concentration palladium aqueous solution.

5. Organic solvent extraction method: Organic solvent extraction method involves contacting palladium aqueous solution with organic solvent, utilizing the selective adsorption of palladium ions by organic solvent, thereby enriching palladium ions from the aqueous phase into the organic phase. Then, an organic phase containing high concentrations of palladium ions is obtained through appropriate solvent extraction, washing, and desorption steps. Finally, palladium ions are reduced to metallic palladium through methods such as heating or electrolysis.

6. Membrane extraction method: The membrane extraction method utilizes special membrane materials to separate and enrich palladium ions from aqueous solutions through the membrane. The membrane extraction method has the advantages of simple operation and good continuity, and is suitable for large-scale palladium water recovery.

2、 Precautions for palladium water recovery

1. Safety protection: The recycling of waste palladium water involves chemicals and high-temperature equipment. Operators should wear personal protective equipment such as protective clothing, goggles, and gloves to ensure operational safety.

2. Equipment maintenance: Recycling waste palladium water requires the use of a series of equipment, such as reactors, filters, reduction furnaces, etc. These equipment require regular maintenance and cleaning to ensure their normal operation and efficient operation.

3. Operation specifications: During the process of recycling waste palladium water, strict adherence to the process flow should be followed to avoid operational errors or incorrect sequence of operations that may lead to waste leakage or poor recycling efficiency.

4. Resource utilization: In the process of recycling waste palladium water, efforts should be made to improve the recovery rate and resource utilization rate as much as possible. By designing and optimizing the process flow reasonably, waste generation can be reduced, and palladium resources in waste palladium water can be recovered and utilized to the maximum extent.

5. Environmental protection: The recycling of waste palladium water is an environmental protection work that should strictly comply with environmental regulations and standards to ensure that the safe disposal and discharge of waste meet environmental protection requirements.

The recycling of waste palladium water is an important environmental protection work. By following reasonable recycling methods, processes, and precautions, efficient, economical, and environmentally friendly recycling of waste palladium water can be achieved, reducing environmental pollution, and maximizing the utilization and recovery of palladium resources. This is of great significance for promoting sustainable development and environmental protection.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;