Recovery of Palladium(II) chloride: several methods and technologies for recovery of Palladium(II) chloride waste

In recent years, the value of palladium has gradually become prominent, especially in the fields of automotive exhaust purification, organic synthesis, and electronic devices. As a common kind of pall

In recent years, the value of palladium has gradually become prominent, especially in the fields of automotive exhaust purification, organic synthesis, and electronic devices. As a common kind of palladium compounds, Palladium(II) chloride (PdCl2) plays an important role in these fields. However, the Scarcity of palladium resources makes the recovery and reuse of Palladium(II) chloride crucial.

The recovery of Palladium(II) chloride is a complex process, which requires an efficient, economical and environmentally friendly method. Several common recovery technologies of Palladium(II) chloride are introduced as follows:

1. Solvent extraction is a commonly used recovery method. In this method, the solution containing Palladium(II) chloride is contacted with the extractant by selecting an appropriate solvent, so that Palladium(II) chloride is transferred from the solution to the extractant. Commonly used solvents include organic solvents such as alcohols, ketones, etc. Solvent extraction has the characteristics of high efficiency and good selectivity, but there are also problems such as difficult solvent recovery and environmental pollution.

2. Ion exchange recovery technology: ion exchange resin has strong selectivity, which can exchange Palladium(II) chloride ions in solution with other ions on the resin, so as to realize the recovery of Palladium(II) chloride. Ion exchange technology is simple to operate and has a lower cost, but requires regular replacement and regeneration of resin.

3. Electrochemical recovery method: This method uses the electrochemical principle, through electrolysis of Palladium(II) chloride solution, Palladium(II) chloride is reduced to palladium metal and deposited on the electrode during electrolysis to achieve recovery. Electrochemical recovery technology has the advantages of high efficiency and no need to add other reagents, but the equipment is complex and the operation is difficult.

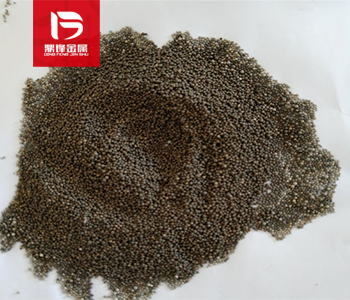

4. Recovery of Palladium(II) chloride by hydrogen reduction method: this method is to heat Palladium(II) chloride to react with hydrogen, so that Palladium(II) chloride can be reduced to metal palladium, so as to achieve recovery. The hydrogen reduction method is simple and cost-effective, but requires reaction under high temperature and high pressure conditions.

To sum up, the recovery of Palladium(II) chloride is a key and complex task. In the recycling process, multiple factors such as recycling efficiency, economy, and environmental friendliness need to be considered. Each recycling technology has its own advantages and disadvantages, and selecting a suitable recycling method requires comprehensive consideration of the actual situation and needs.

With the continuous progress and innovation of technology, it is believed that more efficient and environmentally friendly Palladium(II) chloride recovery technologies will be developed in the future. The sustainable development of Palladium(II) chloride recovery will make an important contribution to the rational utilization of palladium resources and promote the development of related fields. We look forward to more scientific researchers and enterprises making breakthroughs in the field of Palladium(II) chloride recovery and making greater contributions to sustainable development.

As a common palladium compound, Palladium(II) chloride is widely used in the fields of catalysts, electronic devices and chemical synthesis. Because of the Scarcity of palladium, the recovery and reuse of Palladium(II) chloride is particularly important. Efficient recovery of Palladium(II) chloride can be achieved through solvent extraction, ion exchange, electrochemical recovery, hydrogen reduction and other technologies. With the development of technology, it is believed that more environmentally friendly and efficient recycling methods will be developed. The sustainable development of Palladium(II) chloride recovery will promote the rational utilization of palladium resources and the development of related fields. We should strengthen research and application, and work together to achieve sustainable utilization of resources.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;