Palladium and silver slurry recovery, step by step process of recovering palladium and silver slurry waste

Palladium and silver are important precious metals widely used in various industries, including electronics, chemical, medical, and other fields. Over time, the production of waste palladium silver sl

Palladium and silver are important precious metals widely used in various industries, including electronics, chemical, medical, and other fields. Over time, the production of waste palladium silver slurry gradually increases, causing certain pressure on the environment. Therefore, the recovery and reuse of waste palladium silver slurry has become increasingly important. This article will provide a detailed introduction to the steps and processes for recycling waste palladium silver slurry.

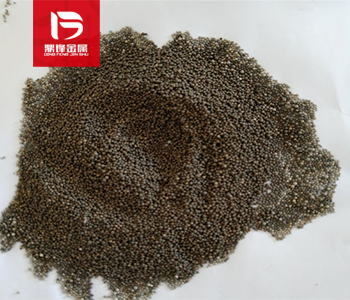

Step 1: Collection of waste palladium silver slurry

The recovery of waste palladium silver slurry first requires collection. These waste materials can come from industrial production processes such as waste, waste electronic products, or waste chemical reagents. When collecting waste palladium silver slurry, attention should be paid to classification and separation for subsequent processing steps.

Step 2: Pretreatment of waste palladium silver slurry

Before recycling waste palladium silver slurry, some pre-treatment steps are required. Firstly, the waste palladium silver slurry needs to be filtered through a sieve to remove impurities and solid particles. Next, some chemical methods, such as acid or alkali washing, can be used to dissolve some insoluble impurities in the solution. In addition, palladium and silver can also be separated through electrolysis and other methods, making subsequent recovery work more efficient.

Step 3: Dissolution of waste palladium silver slurry

Dissolving the waste palladium silver slurry after pretreatment is a Committed step in the recovery process. Usually, a suitable solvent, such as sodium hydroxide or ammonia, is used to dissolve the palladium and silver in the waste palladium silver slurry. This step requires controlling the concentration and temperature of the solvent to ensure complete dissolution of palladium and silver.

Step 4: Precipitation and filtration of waste palladium silver slurry

Add an appropriate amount of precipitant, such as hydrochloric acid or sulfuric acid, to the solution to precipitate palladium and silver from the waste palladium and silver slurry. By adjusting the pH and temperature of the solution, better precipitation effects can be achieved. After sedimentation is completed, the solution is filtered to separate the precipitate from the solution.

Step 5: Palladium silver separation of waste palladium silver slurry

The precipitate contains palladium and silver, which need to be separated. A commonly used method is to dissolve palladium using solvents such as hydrochloric acid or nitric acid, and then separate palladium from silver through electrolysis, extraction, and other methods. The separated palladium and silver can be processed and utilized separately.

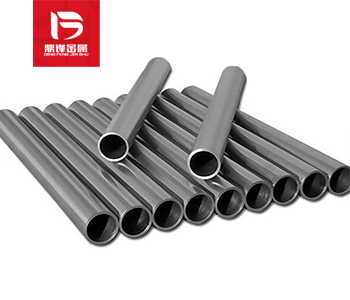

Step 6: Reuse or sales of waste palladium silver slurry

The recovered palladium and silver can be reused or sold. Palladium and silver are both precious metals and have wide applications in many industries. Palladium is often used in catalysts, electronic components, and other fields, while silver is often used in electronics, photography, jewelry, and other fields. Therefore, the recovered palladium and silver can be reprocessed and utilized, reducing the demand for new raw materials and also bringing economic benefits to enterprises.

The recycling of waste palladium silver slurry is an environmentally friendly and economically valuable task. Through steps such as collection, pretreatment, dissolution, precipitation and filtration, palladium silver separation and reuse or sales, precious metals in waste palladium silver slurry can be recovered, achieving resource recycling. This not only helps to reduce the exploitation of natural resources, but also reduces environmental pollution and contributes to sustainable development. Therefore, the recovery of waste palladium silver slurry is of great significance and will continue to be widely applied and promoted in the future.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;