Detailed explanation of the process for recovering rhodium chloride from rhodium chloride waste

Waste rhodium chloride is a waste generated by various industrial processes of rhodium chloride, which contains recyclable rhodium metal and has potential pollution risks to the environment. The recyc

Waste rhodium chloride is a waste generated by various industrial processes of rhodium chloride, which contains recyclable rhodium metal and has potential pollution risks to the environment. The recycling of waste rhodium chloride can not only achieve resource reuse, but also reduce the extraction of natural resources and reduce environmental pollution. Therefore, developing efficient methods for recycling waste rhodium chloride is of great significance for sustainable development.

1、 What is rhodium chloride waste?

Rhodium chloride is a chemical compound composed of rhodium and chlorine elements. It is an inorganic salt with the chemical formula RhCl3. Rhodium chloride exists in various crystal forms, the most common of which is the trihydrate (RhCl3 · 3H2O). Anhydrous rhodium chloride (RhCl3) is a colorless crystal, while rhodium chloride trihydrate (RhCl3 · 3H2O) exhibits light red to reddish brown crystals.

2、 Process flow of extracting rhodium metal with rhodium chloride

1. Raw material treatment: Firstly, the waste rhodium chloride is treated as raw material. This step mainly includes screening, crushing, and drying of waste materials. Screening can remove impurities, crushing helps increase the surface area of the material, facilitating subsequent dissolution and extraction processes, while drying is to reduce energy consumption and processing time in subsequent steps.

2. Dissolution extraction: Next, the waste rhodium chloride treated with raw materials is reacted with a solvent to achieve dissolution extraction of metal rhodium. Common solvents include sodium hydroxide solution or ammonium chloride solution. The reaction conditions include temperature, pressure, and reaction time. During the dissolution extraction process, an appropriate amount of oxidant can be added to promote the reaction.

3. Purification: The solution obtained after dissolution and extraction may contain other metal ions or impurities, which require purification treatment. Common purification methods include ion exchange, solvent extraction, and electrolysis. Ion exchange can separate target metal rhodium by selective adsorption and elution, solvent extraction uses the difference in Partition coefficient between organic phase and aqueous phase for separation, and electrolysis reduces and separates metals by electrode reaction.

4. Precipitation: The target metal rhodium is obtained from the purified solution and needs to be separated through precipitation. Common precipitation methods include reduction precipitation and chemical precipitation. Reduction precipitation usually uses reducing agent to reduce metal ions into metal precipitation. Common reducing agents include hydrogen, sulfur dioxide, Sodium sulfite, etc. Chemical precipitation is to precipitate metal ions by adding precipitants. Common precipitants include sodium hydroxide, sodium carbonate, ammonium chloride, etc.

5. Filtering and washing: The metal rhodium obtained after precipitation needs to be filtered and washed to remove impurities and residual solvents. Filtering is usually done using filter paper or filters, while washing can be done with water or organic solvents.

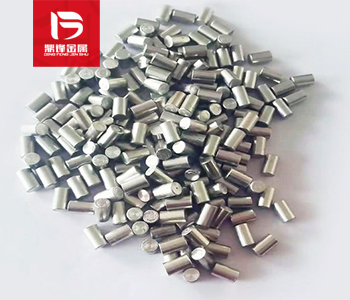

6. Drying and crushing: Finally, dry and crush the filtered and washed rhodium metal. Drying can remove moisture and residual solvents for subsequent storage and use, while crushing can increase the specific surface area of rhodium metal, making it easier to process and use.

The method and process for recovering waste rhodium chloride cover multiple steps such as raw material treatment, dissolution extraction, purification, and precipitation. The process conditions and operating techniques of each step have an impact on the recovery rate and product quality. Therefore, it is necessary to adjust and optimize different raw materials and process parameters in practical applications to achieve efficient and sustainable recycling.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;