How to recycle palladium acetate waste? First, understand the process steps for rhodium acetate recycling

Palladium acetate is an important catalyst widely used in the chemical industry and environmental protection fields. However, a large amount of palladium acetate waste is generated during the producti

Palladium acetate is an important catalyst widely used in the chemical industry and environmental protection fields. However, a large amount of palladium acetate waste is generated during the production process, posing a potential pollution risk to the environment. Therefore, developing effective technologies and methods to recover palladium acetate waste is of great significance. This article will introduce the recovery process and steps of palladium acetate waste.

1、 Background of palladium acetate waste recycling technology

Palladium acetate is an important catalyst with extensive applications in organic synthesis reactions and wastewater treatment. However, a large amount of palladium acetate waste is generated during the production process, including waste catalysts, waste solvents, and waste liquids. These waste materials contain recyclable palladium acetate resources. If not effectively recycled, it not only wastes resources but also may pose potential pollution risks to the environment.

2、 Recovery process of palladium acetate waste

1. Waste classification and separation: Firstly, classify and separate palladium acetate waste. According to the different sources and properties of waste, physical and chemical methods are used to separate the waste for better subsequent recycling and treatment.

2. Chemical extraction: Extract palladium acetate from the waste using appropriate solvents and extractants. Effective separation and recovery of palladium acetate can be achieved through methods such as extraction, solvent extraction, or ion exchange.

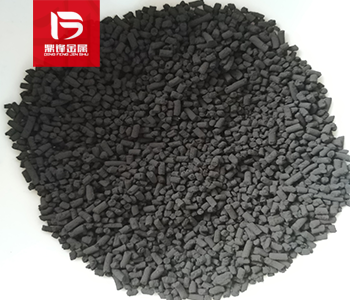

3. Removal of impurities: Palladium acetate waste usually contains some impurities, such as organic matter, metal ions, etc. During the recycling process, it is necessary to remove impurities. Chemical precipitation, adsorption, or membrane separation methods can be used to separate impurities from palladium acetate to obtain high-purity palladium acetate products.

4. Reduction and reuse of palladium acetate: The palladium acetate product obtained through the aforementioned steps is usually in the form of palladium acetate salt or complex. In order to further improve recovery efficiency and reduce costs, it is necessary to reduce palladium acetate to metallic palladium and reuse it. Common reducing agents include hydrogen, ammonia, Sodium sulfite, etc. The reduced palladium can be used for catalyst regeneration, synthesis of new catalysts, and manufacturing of electronic devices.

3、 Advantages of palladium acetate waste recycling process

1. High resource utilization rate: palladium acetate waste contains recyclable palladium acetate resources, which can be fully utilized after recycling to avoid waste.

2. Environmental protection and energy conservation: Through recycling and treatment, the discharge of palladium acetate waste and environmental pollution can be reduced, production costs can be reduced, and the dual benefits of environmental protection and energy conservation can be achieved.

3. Good economic benefits: Palladium acetate is an expensive catalyst that can be recovered and treated to obtain high-quality palladium acetate products, reducing production costs and improving economic benefits.

4、 Application Prospects of Palladium Acetate Waste Recycling Process

With the continuous improvement of environmental protection awareness and the pressure of resource scarcity, the recycling process of palladium acetate waste will be increasingly widely used. Especially in fields such as chemical industry, environmental protection, and electronic device manufacturing, there will be more opportunities and demands to apply palladium acetate waste recycling technology. In the future, with the progress of technology and continuous improvement, the recycling process of palladium acetate waste will achieve a more efficient, economical, and environmentally friendly recycling process.

The technology and methods for recycling acetic acid palladium waste have important application prospects and economic benefits, and have a positive promoting effect on achieving resource recycling and environmental protection and energy conservation. It is necessary to further strengthen research and development, promote continuous innovation and improvement of technology, in order to better meet the needs of industry and society.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;