Rhodium hydride recovery: Rhodium hydride recovery technology, properties, and applications

1、 Properties and applications of rhodium hydrideRhodium hydride (PdHx) is a metal compound with hydrogen adsorption ability, in which rhodium (Pd) serves as a carrier and hydrogen (H) is embedded in

1、 Properties and applications of rhodium hydride

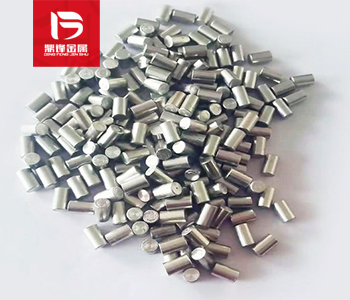

Rhodium hydride (PdHx) is a metal compound with hydrogen adsorption ability, in which rhodium (Pd) serves as a carrier and hydrogen (H) is embedded in the rhodium lattice in an atomic state. Rhodium hydride is widely used in petroleum, chemical, pharmaceutical and other industries due to its good catalytic activity, selectivity and stability. For example, in reactions such as aromatics hydrogenation, olefin acidification, and hemihydrate catalysis, rhodium hydride catalysts play a crucial role.

2、 The necessity of recovering rhodium hydride

Rhodium is a rare precious metal element with limited global reserves and high extraction costs. With the increase of industrial applications, the demand for rhodium continues to rise, leading to high prices of rhodium. In addition, the extraction and extraction process of rhodium generates a large amount of wastewater, exhaust gas, and solid waste, causing serious environmental pollution. Therefore, developing efficient rhodium hydride recovery technology is not only beneficial for saving rhodium resources, reducing production costs, but also helps to reduce environmental pressure.

3、 Rhodium hydride recovery technology

At present, the recovery of rhodium hydride mainly adopts the following methods: 1. Wet recovery: Wet recovery is the extraction of rhodium hydride from waste catalysts through chemical dissolution and precipitation methods. First, waste catalyst is reacted with sodium hydroxide or sulfuric acid solution to generate rhodium hydride solution; Then, by adding reducing agents or other precipitants, the rhodium hydride is precipitated. This method is easy to operate and has low equipment investment, but the recovery rate of rhodium hydride is low, and it will generate a large amount of waste liquid, which needs further treatment. 2. Roasting method for recovery: Roasting method for recovery involves heating waste catalysts to high temperatures to separate rhodium hydride from other components. Firstly, heat the spent catalyst in an atmosphere of oxygen or air to 800-1000 ℃ to decompose rhodium hydride into rhodium powder; Then, rhodium is extracted from other components through chemical leaching or electrochemical treatment. This method has a high recovery rate of rhodium hydride, but it consumes a lot of energy and needs to consider the impact of the generated toxic gases on the environment. 3. Supercritical fluid extraction method: Supercritical fluid extraction method uses supercritical fluid (such as Supercritical carbon dioxide) to extract rhodium hydride from waste catalyst. Supercritical fluid has the characteristics of low viscosity, high diffusivity and high solubility, which can effectively separate rhodium hydride from spent catalyst. This method has a high recovery rate of rhodium hydride and is environmentally friendly, but the equipment investment is large and further cost reduction is needed. 4. Biological recovery: Biological recovery is the use of microorganisms to extract rhodium hydride from waste catalysts. Some microorganisms have the ability to adsorb and reduce metal ions, and can convert rhodium hydride into a recyclable form. This method has lower energy consumption and environmental pollution, but the recovery rate of rhodium hydride is affected by the types of microorganisms and reaction conditions, and further optimization is needed.

The recovery technology of rhodium hydride is of great significance for the conservation of rhodium resources and environmental protection. With the development of science and technology, efforts should be made to increase research on efficient and environmentally friendly rhodium hydride recovery technologies in the future, promote the industrialization process of rhodium hydride recovery technology, and achieve resource recycling and sustainable development.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;