Recovery method and operation steps of palladium anode slime

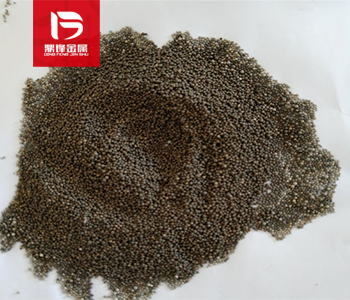

Palladium anode mud is a type of waste containing palladium and other metal elements, usually from industrial production processes such as electroplating and catalyst preparation. Due to palladium bei

Palladium anode mud is a type of waste containing palladium and other metal elements, usually from industrial production processes such as electroplating and catalyst preparation. Due to palladium being a rare and expensive metal, recycling palladium anode slime has become increasingly important. This article will introduce several common methods for recovering palladium anode slime and specific operating methods.

Solvent extraction method is a method of extracting palladium from waste through chemical substances. In this method, palladium in the waste is extracted by an extractant, which then undergoes a series of treatments and recycling to obtain pure palladium. The solvent extraction method can simultaneously recover multiple metal ions, but special caution is needed to avoid pollution and safety issues caused by the extraction agent.

Specific operation methods: (1) Mix the palladium anode mud with the extractant, and stir thoroughly to evenly; (2) Separate the mixture into two layers using a centrifuge, with the upper layer being an organic phase containing an extractant and the lower layer being the substrate; (3) By repeated operations, palladium ions are extracted from the organic phase to form a pure palladium solution; (4) The palladium solution is subjected to a series of treatments and recoveries to obtain pure palladium.

Electrolysis is a method of recovering palladium through electrolysis. In this method, palladium anode mud is used as the anode and electrolyzed in the electrolyte to deposit palladium ions onto the electrode as a solid, ultimately obtaining pure palladium. The electrolysis method can efficiently recover palladium anode slime, as well as other valuable metal ions.

Specific operation methods: (1) Place palladium anode mud into the electrolytic tank as the anode; (2) Add a certain amount of reducing agent to the electrolyte to reduce palladium ions into a solid; (3) Electrify and electrolyze, depositing palladium ions onto the anode to form a solid, ultimately obtaining pure palladium.

Molten salt electrolysis is a method of recovering palladium through high-temperature molten salt. In this method, palladium anode mud is mixed with salt, and then electrolyzed at high temperature to deposit palladium ions onto the electrode as a solid, ultimately obtaining pure palladium. The molten salt electrolysis method can efficiently recover palladium anode slime, but it requires special equipment and high temperature conditions, and special caution is also required to avoid any impact on the environment and human health.

Specific operation methods: (1) Mix palladium anode mud with salt and place it in a melting tank; (2) Heat the melting bath to a high temperature state to melt the salt and palladium anode mud; (3) Electricity is applied for electrolysis, allowing palladium ions to deposit into a solid on the anode, ultimately obtaining pure palladium.

Chemical reduction method is a method of recovering palladium through chemical reactions. In this method, palladium anode mud is reacted with a reducing agent to reduce palladium ions to pure palladium, ultimately obtaining pure palladium. The chemical reduction method is simple to operate, but special caution is required to avoid contamination and safety issues caused by reducing agents.

Specific operation methods: (1) Put the palladium anode mud into a chemical reaction tank, add a certain amount of reducing agent, and mix thoroughly; (2) Wait for the chemical reaction to complete and precipitate the generated pure palladium; (3) Wash palladium with water or other solvents to remove impurities such as reducing agents, and ultimately obtain pure palladium.

The washing method is a method of recovering palladium through steps such as dissolution, filtration, and washing. In this method, palladium anode mud is dissolved in a solution, and then filtered and washed to obtain pure palladium. The washing method is simple to operate, but requires special caution to avoid any impact on the environment and human health.

Specific operation methods: (1) Put palladium anode mud into the solution and dissolve it; (2) Separate impurities through filtration to obtain a solution containing palladium ions; (3) Through multiple washing and precipitation, palladium ions are extracted from the solution, ultimately obtaining pure palladium.

There are various methods for recovering palladium anode slime, and the specific selection of which method should be evaluated and selected based on the actual situation and needs. At the same time, special attention should be paid to safety issues during operation and appropriate measures should be taken to avoid damage to the environment and human health. In addition, recycling palladium anode mud can not only reduce resource waste and environmental pollution, but also improve the economic benefits and social image of enterprises, which has important economic and environmental significance.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;