From Waste to Value: Revealing the Recovery Process of Colloidal Palladium

In recent years, there has been an increasing need for an effective and sustainable method to extract valuable materials from industrial waste. Palladium is such a material that is a precious metal wi

In recent years, there has been an increasing need for an effective and sustainable method to extract valuable materials from industrial waste. Palladium is such a material that is a precious metal with significant value in many applications, including electronic products, automotive catalytic converters, and the dental industry. The colloidal palladium recovery process is an innovative solution that meets the needs of reliable, cost-effective, and environmentally friendly methods for extracting palladium from waste. This article will delve into the recovery process and benefits of colloidal palladium. The importance of recovering palladium. Palladium is a rare and valuable metal with a wide range of uses. Its unique characteristics make it highly sought after in various industries. However, palladium is becoming increasingly scarce, leading to a surge in its market price. In order to meet the growing demand for this precious metal, companies are turning to innovative solutions that can recover palladium from waste. One of the methods is the colloidal palladium recovery process, which provides a sustainable and effective method for extracting this valuable metal.

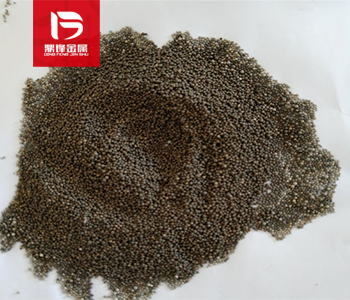

Overview of Colloidal Palladium Recovery Process Colloidal Palladium Recovery Process is a cutting-edge technology that relies on the principles of colloidal chemistry to extract palladium from waste. This process can be applied to various types of waste, including electronic waste (e-waste), automotive catalysts, and dental materials. This process involves the following steps: pre-treatment: The waste first undergoes pre-treatment to decompose its components and expose palladium particles. This may involve processes such as crushing, grinding, and screening to obtain fine powder. Leaching: Leaching the treated waste and then mixing it with a suitable solvent that can dissolve palladium. The choice of solvent depends on the type of waste and the efficiency required by the process. Some common solvents include aqua regia (a mixture of nitric acid and hydrochloric acid), cyanide solution, and thiourea.

The formation of colloidal palladium: By adding a reducing agent, the dissolved palladium is converted into colloidal palladium. This step causes palladium ions to aggregate into small particles, forming a colloidal suspension. The selection of reducing agents is crucial as it determines the size, shape, and stability of colloidal palladium particles. Common reducing agents include Sodium borohydride, hydrazine and ascorbic acid. Separation and purification: Then, various techniques are used to separate colloidal palladium particles from the waste liquid, such as filtration, centrifugation, or precipitation. Then, further purification processes such as washing and roasting are carried out on the separated particles to remove impurities and improve the purity of the recovered palladium. Recovery: The purified colloidal palladium particles can be converted back into metallic palladium through processes such as roasting or chemical reduction.

Advantages of Colloidal Palladium Recovery Process

The colloidal palladium recovery process has several benefits, including efficiency: this process allows for selective recovery of palladium, thereby obtaining high-purity products. This eliminates the need for multiple purification steps and reduces overall processing time. Environmental protection: The recovery process of colloidal palladium uses relatively mild reagents, which poses less harm to the environment compared to traditional recovery methods that use strong acids and toxic chemicals. Resource conservation: By recycling and reusing palladium from waste, the demand for newly mined palladium is reduced. This helps to protect natural resources and promote a circular economy. Cost effectiveness: This process is more cost-effective than traditional methods as it requires fewer chemicals and purification steps. In addition, recovered palladium can be sold or reused, generating revenue and reducing waste treatment costs.

The colloidal palladium recovery process is a promising technology that can efficiently and environmentally recover this valuable metal from waste. By converting waste into value, this process helps to save resources and promote a more sustainable future. With the continuous growth of demand for palladium, the importance of effective recovery methods such as colloidal palladium recovery cannot be overemphasized. By adopting and refining this process, industry can reduce its impact on the environment and optimize the use of this precious metal.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;