Palladium Recovery_ Methods of Recovering Palladium and Refining Palladium from Palladium Ore or Palladium Waste

Methods of Palladium Recovery_Recovering and Refining Palladium from Palladium Ore or Palladium Waste Palladium, a precious metal with applications in electronics, automotive catalytic converters, and

Methods of Palladium Recovery_Recovering and Refining Palladium from Palladium Ore or Palladium Waste

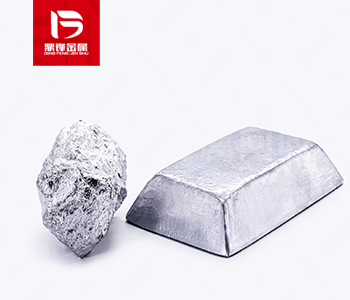

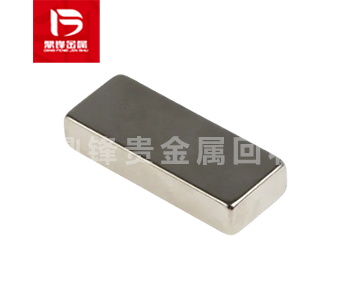

Palladium, a precious metal with applications in electronics, automotive catalytic converters, and jewelry, is often recovered from various sources, including electronic waste and spent catalysts. The recovery process involves several methods, each with its own advantages and challenges.

1. Hydrometallurgical Methods

Hydrometallurgy is a widely used technique for recovering palladium from various materials. This method typically involves leaching, where an acidic or alkaline solution dissolves the palladium. Common leaching agents include aqua regia (a mixture of hydrochloric and nitric acids) and cyanide solutions. After leaching, the palladium can be precipitated out of the solution using chemical reagents, such as ammonium chloride, forming palladium salts that can be converted back to metallic form.

One significant advantage of hydrometallurgical methods is their ability to selectively extract palladium from complex mixtures, making them ideal for recovering palladium from electronic waste. However, these methods can also be costly and require careful handling of hazardous chemicals.

2. Pyrometallurgical Methods

Pyrometallurgy involves the recovery of palladium through high-temperature processes, such as smelting. In this method, materials containing palladium are subjected to extreme heat, causing the metals to melt and separate from non-metallic impurities. This technique is often used for recycling spent catalysts from automotive systems.

While pyrometallurgy is effective for bulk recovery, it may result in lower yields compared to hydrometallurgical methods, particularly when recovering palladium from low-grade sources. Additionally, the energy requirements for high-temperature processes can be significant, raising environmental concerns.

In conclusion, palladium recovery can be achieved through various methods, each with distinct advantages and limitations. The choice of method often depends on the source of palladium, the desired purity level, and economic considerations. As technology continues to evolve, more efficient and environmentally friendly recovery methods are likely to emerge, contributing to the sustainability of palladium recycling.

Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price.