Palladium Recovery_Methods of Palladium Recycling and refining

palladium recycling employs various methods that cater to different waste sources and recovery requirements. By optimizing these processes and incorporating new technologies, industries can enhance palladium recovery and contribute to a more sustainable future.

Methods of Palladium Recycling

Palladium recycling involves various methods that facilitate the extraction of this valuable metal from diverse sources, including automotive catalysts and electronic waste. Understanding these methods is crucial for maximizing recovery efficiency and ensuring the sustainability of palladium resources.

1. Hydrometallurgical Methods

One of the most common approaches to palladium recycling is hydrometallurgy, which involves using aqueous solutions to extract the metal from waste materials. The process typically starts with leaching, where an acid or alkaline solution dissolves palladium from the substrate. Common leaching agents include aqua regia and thiourea solutions. After leaching, palladium is recovered from the solution through precipitation or solvent extraction techniques, resulting in high-purity palladium salts that can be refined back to metallic form.

Hydrometallurgical methods are particularly advantageous for recovering palladium from complex matrices, such as electronic waste, due to their selectivity and efficiency. However, these methods require careful handling of hazardous chemicals, and the disposal of spent solutions must be managed properly to minimize environmental impacts.

2. Pyrometallurgical Methods

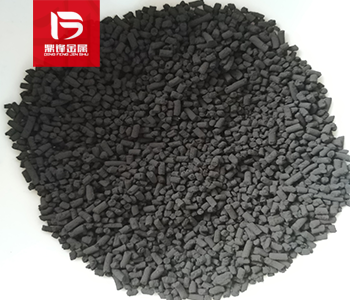

Pyrometallurgy is another widely used method for recycling palladium, especially from spent catalysts. This technique involves high-temperature processes, such as smelting, where materials containing palladium are heated to separate the metal from impurities. The palladium is then recovered as a metal alloy or in its pure form.

While pyrometallurgical methods can be effective for bulk recovery, they tend to consume more energy and may result in lower recovery rates compared to hydrometallurgy, particularly for low-grade materials. Nonetheless, they are often employed for large-scale operations due to their simplicity and effectiveness.

3. Emerging Technologies

Recent advancements in recycling technologies have introduced innovative approaches for palladium recovery. Biotechnological methods, such as bioleaching, utilize microorganisms to extract palladium from waste materials. These environmentally friendly methods offer the potential for selective recovery and lower environmental impact.

As technology continues to evolve, hybrid methods that combine traditional and emerging techniques may provide even greater efficiency and sustainability in palladium recycling. The development of these new technologies is crucial for meeting the growing demand for palladium while minimizing ecological consequences.

In summary, palladium recycling employs various methods that cater to different waste sources and recovery requirements. By optimizing these processes and incorporating new technologies, industries can enhance palladium recovery and contribute to a more sustainable future.

Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price.