Platinum oxide recovery_ Adams catalyst recovery_ Precious metal recycling manufacturers

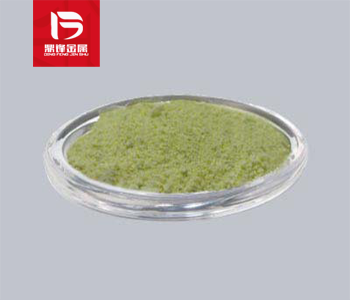

Platinum oxide is a chemical substance with the chemical formula PtO2. It is an inorganic compound composed of platinum and oxygen elements. Platinum oxide is a black solid powder.

Product Details

Platinum oxide is a chemical substance with the chemical formula PtO2. It is a Inorganic compound composed of platinum and oxygen element, and platinum oxide is in the form of black solid powder. Platinum oxide has various chemical and physical properties, and as a semiconductor material, it has a certain conductivity. At room temperature, the conductivity of platinum oxide is low, but as the temperature increases, its conductivity will increase. In addition, platinum oxide is also a stable compound that can withstand acid and alkali attack. It has a high melting point and good thermal stability.

There are several different ways to prepare platinum oxide, and the following are the methods for preparing platinum oxide:

1. Direct oxidation method: This is one of the most commonly used methods for preparing platinum oxide. This method involves exposing platinum metal to oxygen at high temperatures, allowing it to react with oxygen to generate platinum oxide. This process needs to be carried out at appropriate temperature and oxygen concentration to ensure the progress of the reaction and the purity of the product.

2. Thermal decomposition method: This is a commonly used method for preparing platinum oxide. First, Chloroplatinic acid (H2PtCl6) is dissolved in water to obtain platinum chloride complex solution. Then, the solution is heated to an appropriate temperature, and Chloroplatinic acid is decomposed into platinum oxide and hydrochloric acid (HCl) through thermal Chemical decomposition. Finally, pure platinum oxide is obtained through steps such as filtration and washing.

3. Hydrothermal synthesis: This is a method of preparing platinum oxide in high-temperature and high-pressure water environment. First, mix an appropriate amount of platinum salt (such as Chloroplatinic acid or platinum nitrate) with a certain proportion of alkaline solution. Then, place the mixture in a closed container and react under high temperature and pressure conditions. In the process of hydrothermal synthesis, platinum salts react with oxygen in an alkaline solution to form platinum oxide. Finally, pure platinum oxide powder is obtained through steps such as filtration, washing, and drying.

Waste platinum oxide is one of the recycling sources of platinum containing precious metal catalyst waste. The recycling sources of platinum containing precious metal catalyst waste include platinum chloride recovery, platinum asbestos recovery, platinum carbon catalyst recovery, platinum nitrate recovery, platinum salt recovery, Chloroplatinic acid recovery, etc. If you have any demand for waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has independent recycling and refining factories without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.