Recovery of platinum rhenium catalyst_ Platinum catalyst recovery price_ Precious metal catalyst recovery and refining manufacturer

Platinum-rhenium catalyst is an alloy catalyst composed of platinum (Pt) and rhenium (Re). This catalyst is widely used in petrochemical, chemical synthesis and environmental protection fields due to its excellent activity, selectivity and stability. Platinum-rhenium catalyst can improve the performance of fuel cells, enhance the adsorption and desorption capacity of hydrogen, effectively reduce the load of catalysts, and show good catalytic activity in processes such as water-gas shift and ammonia oxidation denitrification.

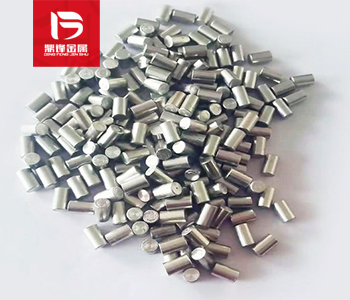

Product Details

1、 Introduction to Platinum Rhenium Catalysts

Platinum rhenium catalyst is an alloy catalyst composed of platinum (Pt) and rhenium (Re). Because of its excellent activity, selectivity and stability, this catalyst is widely used in petrochemical industry, chemical synthesis, environmental protection and other fields. Platinum rhenium catalyst can improve the performance of fuel cell, enhance the adsorption and desorption capacity of hydrogen, effectively reduce the load of catalyst, and show good catalytic activity in Water gas shift, Ammoxidation denitrification and other processes.

2、 Preparation of Platinum Rhenium Catalysts

There are various preparation methods for platinum rhenium catalysts, and the following are common methods: 1. Impregnation method: A simple impregnation method is used to prepare platinum rhenium catalysts. An appropriate amount of platinum salt and rhenium salt solution is immersed on the surface of the carrier, and after drying and reduction treatment, platinum rhenium catalysts can be obtained. 2. Chemical reduction method: The platinum rhenium catalyst is prepared by chemical reduction method. Firstly, the platinum salt and rhenium salt are dissolved in water, and then a reducing agent such as ammonia or mercaptan is added. After stirring, filtering, washing, and drying, the platinum rhenium catalyst can be obtained. 3. Sol gel method: Sol gel method can effectively control the particle size and morphology of the catalyst. By dissolving platinum salt and rhenium salt in appropriate solvent, adding gel agent, through gel, drying, reduction and other processes, platinum rhenium catalyst with uniform distribution is prepared. 4. Supercritical fluid method: The platinum rhenium catalyst is prepared by supercritical fluid method, which can achieve accurate control of particle size and morphology by adjusting the process conditions, and improve the performance of the catalyst. Generally, supercritical CO2 is used as solvent to dissolve platinum salt and rhenium salt and inject them into supercritical fluid, and then precipitate metals through rapid expansion process to form evenly distributed platinum rhenium particles. 5. Coprecipitation method: The coprecipitation method is to form a precipitate from a platinum rhenium solution under certain conditions, and then prepare a platinum rhenium catalyst through steps such as filtration, washing, drying, and reduction. This method can ensure uniform metal loading and effectively reduce the preparation cost of the catalyst.

Waste platinum rhenium catalyst is one of the recycling sources of platinum containing noble metal catalyst waste. The recycling sources of platinum containing noble metal catalyst waste include platinum oxide recovery, platinum chloride recovery, platinum carbon catalyst recovery, platinum nitrate recovery, platinum iodide recovery, Ammonium hexachloroplatinate recovery, etc. If you have any demand for waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has independent recycling and refining factories without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.