Dingfeng Closed-Loop Platinum Catalyst Recycling Program

Industrial catalysts containing platinum group metals (PGMs) — platinum, palladium, and rhodium — represent both a regulatory liability and a financial opportunity.

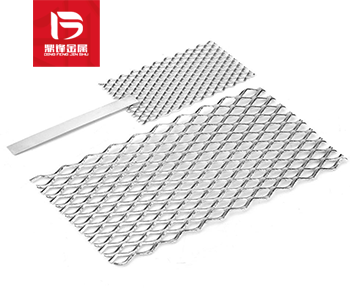

Product Details

The Business and Environmental Case for Recycling

Industrial catalysts containing platinum group metals (PGMs) — platinum, palladium, and rhodium — represent both a regulatory liability and a financial opportunity:

12–18% average PGM content in spent petroleum catalysts

300% price volatility in virgin PGM markets over the last 5 years

75% reduction in Scope 3 emissions when replacing mined PGMs with recycled metals

Dingfeng’s ISO 14001-certified process enables customers to realize substantial ESG and economic gains, supporting circular economy goals with confidence.

Technical Process Overview

Stage 1: Material Characterization

Precision XRF and ICP-MS analysis to determine exact PGM content

Hazardous material screening in compliance with the Basel Convention

Stage 2: Hydrometallurgical Extraction

Proprietary lixiviant formulations (patent pending) tailored for catalyst types

Counter-current decantation for optimized metal recovery

On-site wastewater regeneration to ensure minimal environmental footprint

Stage 3: Metal Refining

Electrowinning for high-efficiency PGM recovery

Ion exchange systems to extract valuable rare earth elements

Final product purity: 99.95%, compliant with ASTM B761 standards

Performance Benchmarks

| Parameter | Industry Standard | Dingfeng Performance |

|---|---|---|

| PGM Recovery Rate | 85–90% | 95–97% |

| Processing Time | 6–8 weeks | 3–4 weeks |

| Residual Waste | 15–20% | <5% |

Revenue-sharing models to align incentives and reduce CAPEX burden

Real-time tracking via secure customer portal

ITAR-compliant handling for sensitive and defense-related materials

Request a Technical Assessment

To initiate your assessment, please provide catalyst specifications (type, volume, and any available analysis reports) to:

Dingfeng Materials Science Team

[Email]:dfpmr5719@dfpmr.com [WhatsApp]+8613760175719