Gold plating slag recycling: Detailed introduction to the specific process of gold plating slag recycling

Gold plating slag usually contains a certain proportion of precious metals, such as gold, silver, and platinum. These precious metals are widely used in industries such as electronic equipment, commun

Gold plating slag usually contains a certain proportion of precious metals, such as gold, silver, and platinum. These precious metals are widely used in industries such as electronic equipment, communication equipment, medical equipment, and jewelry. Due to the fast update and replacement speed of these devices, many old equipment and waste have accumulated a large amount of gold plating slag. The specific process of recovering gold plating slag will be introduced in detail below.

The specific process of recovering gold plating slag is as follows:

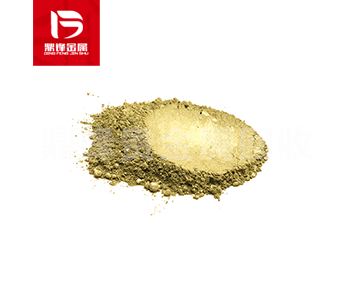

1. Collection and screening of raw materials: the first step of gold plating slag recycling is to collect Industrial waste and waste from different industries. These waste materials include electronic waste, electroplating waste liquid, discarded circuit boards, and other waste materials containing gold. Then, conduct preliminary screening and classification to separate the waste from different sources.

2. Crushing and grinding: The collected waste is screened and further crushed and ground. This step aims to convert the waste into smaller particles, increase the surface area, and facilitate subsequent chemical reactions.

3. Pickling and dissolution: The ground waste will be placed in an acidic solution for pickling and dissolution. The commonly used acid solution is a mixture of concentrated nitric acid and hydrochloric acid, which can effectively dissolve non gold impurities, while gold is not affected.

4. Precipitation and filtration: After acid washing and dissolution, a gold salt solution containing gold will be formed in the solution. In order to separate gold, it is necessary to precipitate it by adding chemical reagents. The commonly used chemical reagent is ammonia water, which reacts with gold salts to form precipitates. After the precipitation is formed, the solid particles in the solution are separated by filtration.

5. Gold precipitation treatment: The gold precipitate separated through filtration will be further treated to remove impurities. This step typically involves electrolysis and high-temperature treatment. Electrolysis is the process of placing gold precipitates in an electrolytic cell and separating impurities from the gold through the action of an electric current. High temperature treatment involves heating the gold precipitate to a high temperature, causing impurities to evaporate or transform into easily separable forms.

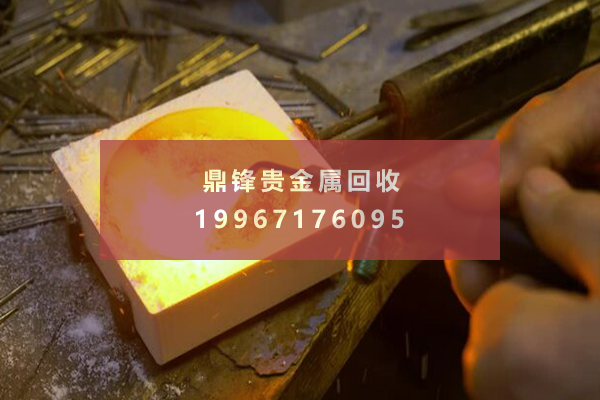

6. Smelting and purification: The treated gold precipitate usually contains some other precious metals and impurities. In order to obtain pure gold, smelting and purification are necessary. Melting is the process of depositing gold in a high-temperature furnace to melt it into a liquid state. By controlling the temperature and adding chemical reagents, impurities can be further removed. Pure gold will gradually precipitate during the smelting process, forming metal blocks.

7. Refining and separation: The gold metal blocks obtained by smelting need to undergo refining and separation processes to improve their purity. This step usually uses electrolysis or chemical separation methods. By placing a gold metal block in an electrolytic cell and separating impurities through the action of an electric current, a purer gold is obtained. Chemical separation utilizes different chemical properties to separate impurities from gold.

8. Quality testing and finished product preparation: Finally, the gold sample obtained from the recycling process needs to undergo quality testing to determine its purity and quality. Common detection methods include mass spectrometry, spectral analysis, and chemical analysis. Once the quality of the gold sample is qualified, finished product preparation can be carried out, such as making gold bars, coins, or other gold products.

The gold plating slag recovery process includes multiple steps, including raw material collection and screening, crushing and grinding, acid washing and dissolution, precipitation and filtration, gold precipitation treatment, smelting and purification, refining and separation, as well as quality testing and product preparation. The goal of these steps is to extract pure gold from Industrial waste and waste, and ensure that the recycling process meets environmental and safety requirements.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;