Silver Contact Recycling and Extraction: Extracting Precious Silver from Electronic Waste

The development of the electronic industry has made most people have many electronic products around them, and most electronic products are essential. However, the short lifespan of these products has

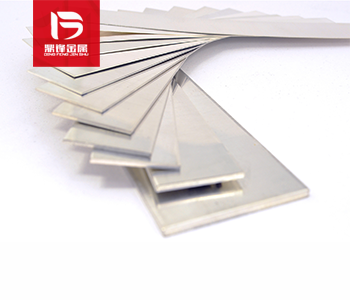

The development of the electronic industry has made most people have many electronic products around them, and most electronic products are essential. However, the short lifespan of these products has made electronic waste disposal a global challenge. Among these wastes, a component called "silver contact" has attracted widespread attention. Silver contacts are key components in many electronic devices, and are widely used in products such as switches and contactors due to their excellent conductivity and oxidation resistance. This article will explore the recovery of silver contacts and the process of extracting silver.

Method for recovering silver contacts

Physical methods: Physical methods include screening, magnetic separation, etc. Screening involves separating silver contacts from other electronic waste through a sieve, while magnetic separation uses magnetic force to separate magnetic materials from silver contacts. These two methods are simple and feasible, but may not be able to completely separate the silver contacts.

Chemical methods: Chemical methods mainly include leaching method, cyanide method, etc. These methods can more effectively separate silver contacts, but the operation is complex and may produce harmful chemicals.

3、 The process of extracting silver from silver contacts

1. Pre treatment: First, the recovered silver contacts are crushed to make them more easily processed small particles. Next, the particles are mixed to improve the uniformity of silver content in the silver contacts. 2. Chemical leaching: Use an appropriate chemical solvent, such as nitric acid or hydrochloric acid, to soak the silver contacts in the solvent. Under certain conditions of time, temperature, and concentration, silver will dissolve in the solvent, forming a silver containing solution. 3. Filtration and precipitation: Filter the silver containing solution to remove undissolved impurities. Then, add a reducing agent, such as Sodium persulfate or Iron(II) sulfate, to the solution. These reducing agents can reduce silver ions in the solution to metallic silver and precipitate it. 4. Washing and drying: Wash the sediment with water to remove residual chemicals. Subsequently, it was dried at low temperature to obtain dry metallic silver powder. 5. Melting and purification: Put dry metal silver powder into a melting furnace and melt at high temperature. During the melting process, an appropriate amount of flux can be added to reduce the melting point and promote the separation of silver and impurities. The molten silver liquid is cooled and solidified to form silver ingots. 6. Electrolytic purification: Using silver ingots as anodes and high-purity silver as cathodes, immerse them in an electrolyte containing silver ions. Under the action of current, the silver on the anode gradually dissolves, and the cathode deposits high-purity silver. After electrolytic purification, silver with a purity of up to 99.99% can be obtained.

Silver contact recycling and extraction of silver is an effective resource utilization method that helps alleviate the pressure on silver demand. By recycling through physical and chemical methods, followed by a series of processes such as pre-treatment, chemical leaching, filtration precipitation, washing and drying, smelting, and electrolytic purification, discarded silver contacts can be successfully converted into precious silver. In the future, with the continuous progress of technology, research in this field will become more in-depth, improving the efficiency and environmental friendliness of recycling and refining, making silver contact recycling and refining a more sustainable way of resource utilization.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;