Silver plating recycling_A brief introduction to the methods and technologies of silver contact recycling

With the continuous growth of demand for electronic products, the demand for mining precious metals such as silver is also growing. Although silver is an essential component in electronic products, it

With the continuous growth of demand for electronic products, the demand for mining precious metals such as silver is also growing. Although silver is an essential component in electronic products, it is not infinite and must be recycled as much as possible. A valuable application of silver recycling is to recycle silver contacts from electronic components such as switches or relays. In this article, we will discuss the methods and techniques used in silver contact recovery.

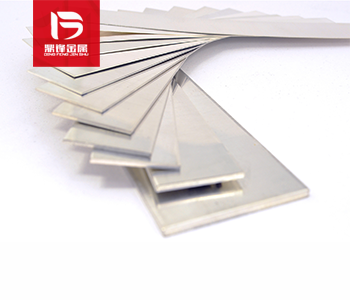

Silver contact recovery is the process of recovering silver from electrical contact, which is a small metal in contact with each other and allows for the flow of current. These contacts can be found in many electronic devices, such as switches, sockets, and relays. Due to silver being a valuable and expensive metal, it is important to recycle it in order to reduce waste and save costs. The first step in recycling silver contacts is to collect them. This is usually accomplished by disassembling electronic devices and manually removing contacts. Once the contacts are collected, they will be treated to remove any pollutants such as dirt or oil. This is usually accomplished through chemical cleaning or ultrasonic cleaning. After cleaning, the contacts will be classified by type and size. This is important as different types of contacts may require different recovery methods. For example, contacts made of different metals may have different melting points, which may affect the recovery process.

The next step in recovering silver contacts is to separate silver from other metals in the contacts. There are several methods that can be used for this, including smelting, electroplating, and chemical precipitation. Melting involves heating the contacts to a high temperature so that the metal can melt and separate. This method is usually used for a large number of contacts and requires specialized equipment. The working principle of electroplating is to apply a thin layer of silver on the contacts. This is achieved by immersing the contacts in a silver salt solution and introducing an electric current to deposit silver onto the contacts. This method is usually used for a small number of contacts.

Chemical precipitation method is another commonly used method for silver contact recovery. This method involves adding a chemical solution to the contacts, which can cause silver to precipitate from the solution. Then the silver can be filtered and collected. This method is usually used for a small number of contacts. Once silver is separated from other metals in the contacts, it can be refined to remove any impurities. This is usually achieved by melting silver and then pouring it into a mold to form pure silver bars or ingots. It is important to note that silver contact recycling can be a dangerous process and caution must be exercised when handling the contacts and chemicals involved. Protective equipment such as gloves and goggles should always be worn, and the recovery process should be carried out in a well ventilated area. In addition to traditional silver contact recycling methods, newer and more innovative methods are also being developed. One way is to use bacteria to recover silver from Electronic waste. Researchers have found that certain types of bacteria can dissolve metals, including silver, and store them inside cells. This method is still in the experimental stage, but has shown promising results.

Silver contact recycling is a valuable process for recovering silver from electronic components. This process involves the collection, cleaning, classification, separation, and refining of contacts, which can be carried out using various methods, including smelting, electroplating, chemical precipitation, and renewal, as well as more innovative methods such as bacterial recovery. It is important to take preventive measures when dealing with contacts and the chemicals involved, and ensure that the recycling process is carried out in a safe and environmentally responsible manner.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;