Iridium spark plug recycling_ Automobile spark plug recycling_ Spark plug recycling manufacturer

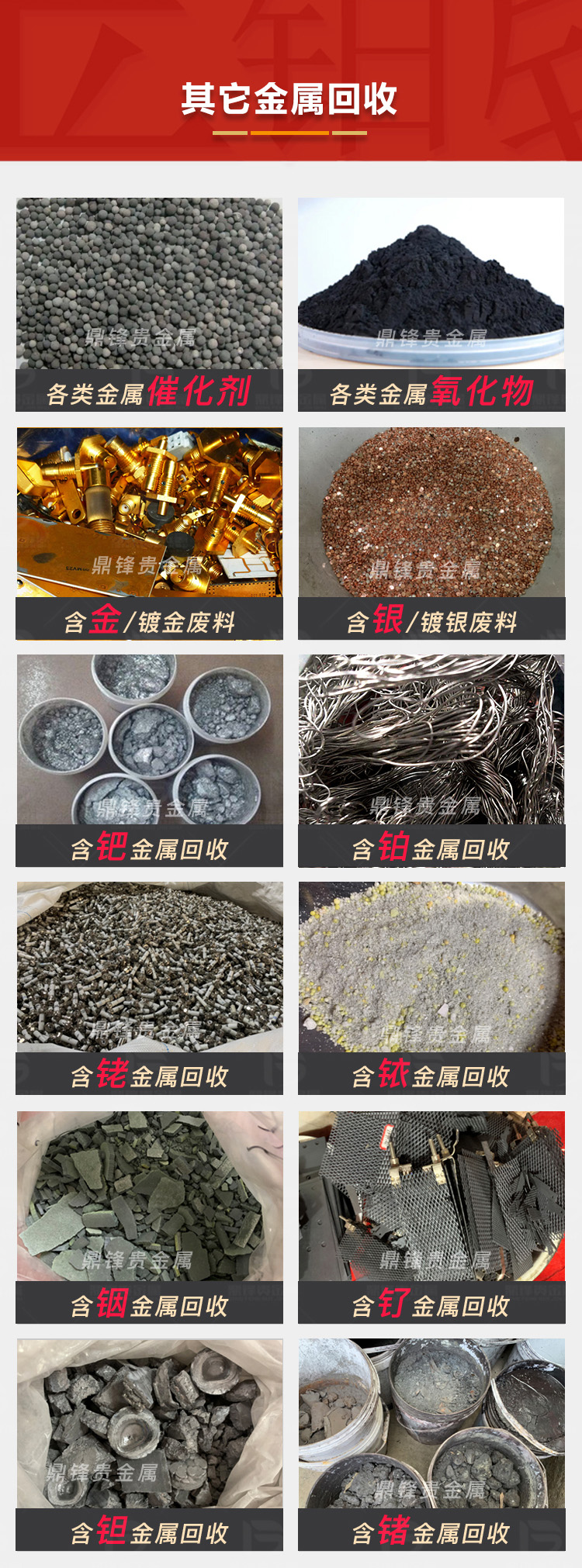

In today's automotive industry, engine performance has always been one of the focuses of attention. In order to achieve higher combustion efficiency and lower emission levels, various technological innovations have been introduced into the design of the engine. Among these innovations, the iridium spark plug is undoubtedly an important part of engine optimization. Waste iridium spark plugs are one of the sources of waste car spark plug recycling, waste car spark plug recycling sources include platinum spark plug recycling, ruthenium spark plug recycling, iridium platinum spark plug recycling, osmium gold spark plug recycling, double iridium spark plug recycling, etc.

Product Details

The Process of Spark Plug Recycling

Introduction

The recycling of spark plugs is a critical aspect of managing automotive waste effectively. Spark plugs contain valuable materials that, when recycled, can significantly reduce the environmental impact associated with their disposal. This essay outlines the various steps involved in the recycling process of spark plugs, from collection to material recovery.

Collection and Sorting

The recycling process begins with the collection of used spark plugs from automotive service centers, repair shops, and individuals. These plugs are then sorted based on their type and condition. Effective sorting is crucial, as different spark plug types may contain varying amounts of recoverable materials. Sorting ensures that recyclers can efficiently process the plugs and maximize recovery rates.

Processing

Once sorted, the spark plugs are cleaned to remove any contaminants, such as oil or dirt. This step is essential for ensuring the quality of the recycled materials. After cleaning, the spark plugs undergo a mechanical process where they are crushed or shredded. This breaks them down into smaller pieces, making it easier to extract valuable materials.

Material Recovery

The next step in the recycling process involves separating the various materials contained within the spark plugs. This typically includes metals such as aluminum, nickel, and precious metals like platinum and palladium. Advanced techniques, such as hydrometallurgical and pyrometallurgical methods, are often used to extract these metals from the crushed spark plug material. These processes help recover a high percentage of the valuable components, contributing to the overall sustainability of the recycling effort.

Final Products

After the materials have been recovered, they are refined and processed into new products. Recycled aluminum, for example, can be used to manufacture new spark plugs or other automotive components. Precious metals recovered from spark plugs can be reused in various industries, including electronics and jewelry. This not only conserves resources but also reduces the environmental impact of mining new metals.

Conclusion

The recycling process of spark plugs is a vital component of sustainable automotive practices. By understanding the steps involved in collecting, processing, and recovering materials from spark plugs, we can appreciate the importance of recycling in minimizing waste and conserving valuable resources. As consumers and businesses become more aware of the benefits of recycling, the impact of spark plug recycling will continue to grow.