What’s Inside a Spark Plug? The Precious Metal Hidden in Plain Sight

Spark plugs are more than engine parts—they’re micro-reservoirs of critical resources. Recycling them isn’t just about sustainability; it’s about unlocking materials that drive human progress. Companies like Dingfeng are pioneering this transformation, proving that advanced technology and global collaboration can turn everyday waste into tomorrow’s innovations.

Product Details

Introduction

A spark plug might seem like a humble automotive part, but beneath its rugged exterior lies a treasure trove of rare and valuable materials. Often overlooked, these components are engineered with precision and packed with metals critical to both performance and sustainability. Let’s dismantle a spark plug to reveal its secrets—and explore why recovering its hidden riches is a game-changer for industries worldwide.

Breakdown of Materials: Anatomy of a Spark Plug

Electrode Tips (The Precious Core)

Material: Platinum, iridium, or palladium.

Why? These metals withstand extreme temperatures (up to 2,500°C) and resist corrosion, ensuring longevity in high-stress engine environments.

Content per plug: 0.1–0.3 grams of PGMs (platinum-group metals).

Shell (The Protective Armor)

Material: Steel coated with nickel alloy.

Purpose: Provides structural integrity and heat dissipation.

Insulator (The Electrical Guardian)

Material: Aluminum oxide ceramic.

Role: Prevents electrical leakage and withstands 30,000+ volts.

Why Iridium? The Crown Jewel of Spark Plugs

Iridium is one of Earth’s rarest elements—40 times scarcer than gold—with just 3 metric tons mined globally each year. Its exceptional properties make it indispensable:

Melting point: 2,446°C (higher than titanium or platinum).

Durability: Lasts up to 100,000 miles in modern spark plugs, outperforming copper or nickel alternatives.

Applications beyond autos: Recycled iridium is vital for spacecraft thrusters, pacemakers, and OLED screens.

The Extraction Challenge: Mining Micro-Metals

Recovering PGMs from spark plugs is like finding needles in a haystack. Traditional methods struggle with:

Low concentrations: Extracting 1 gram of iridium requires processing ~1,000 spark plugs.

Complex chemistry: PGMs are fused with ceramics and alloys, demanding precise separation.

Cost inefficiency: Small-scale refining often outweighs material value.

Dingfeng’s Innovation: Turning Complexity into Opportunity

Dingfeng’s proprietary refining process overcomes these hurdles:

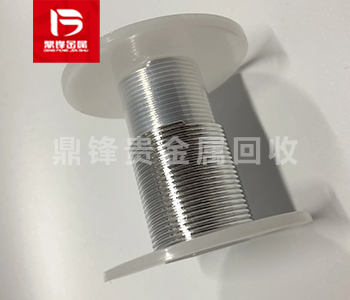

Crushing & Sorting: Magnets and eddy-current separators isolate metal-rich components.

Acid Leaching: Hydrometallurgical techniques dissolve PGMs without damaging their structure.

Electrolytic Recovery: Purifies metals to 99.95% purity, meeting industrial standards.

This method recovers >95% of PGMs at half the cost of mining, transforming “waste” into a revenue stream.

Beyond the Spark: The Ripple Effect of Recycling

Recycled PGMs from spark plugs power innovations across industries:

Aerospace: Iridium alloys shield rocket engines from re-entry heat.

Healthcare: Platinum is used in chemotherapy drugs and pacemaker electrodes.

Tech: Palladium is essential for microchips and hydrogen fuel cells.

By recycling 10,000 spark plugs, we salvage enough iridium to manufacture 50 life-saving medical devices—a testament to the circular economy’s potential.

Conclusion: Small Component, Big Legacy

Spark plugs are more than engine parts—they’re micro-reservoirs of critical resources. Recycling them isn’t just about sustainability; it’s about unlocking materials that drive human progress. Companies like Dingfeng are pioneering this transformation, proving that advanced technology and global collaboration can turn everyday waste into tomorrow’s innovations.

Next time you replace a spark plug, remember: You’re holding a tiny piece of the future. Recycle it wisely.

Key Stats at a Glance

1 ton of spark plugs ≈ 7 grams of iridium (worth ~$1,050).

1 recycled spark plug saves 1.5 kg of CO₂ emissions.

60% of global iridium is used outside the automotive sector.