The Science Behind Extracting Precious Metals from Spark Plugs

The process of recovering platinum and iridium from spark plugs involves sophisticated metallurgy. This article explains the technical aspects of precious metal refining.

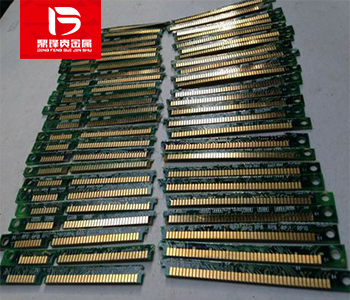

Product Details

The process of recovering platinum and iridium from spark plugs involves sophisticated metallurgy. This article explains the technical aspects of precious metal refining.

1. Spark Plug Composition Analysis

- Typical precious metal locations:

- Platinum: Center electrode tip/welding point

- Iridium: Fine center electrode needle

Base materials (steel shell, ceramic insulator) have no value

2. Industrial Refining Process Steps

- Mechanical separation (crushing/grinding)

- Chemical dissolution (aqua regia for platinum, specialized acids for iridium)

- Precipitation and purification

- Electrolytic refining for 99.95%+ purity

3. Challenges in Spark Plug Recycling

- Small quantities per unit (0.1-0.5g per plug)

- Mixed materials require careful separation

- High-purity requirements for industrial reuse

4. Yield Optimization Techniques

- Advanced sorting to prevent cross-contamination

- Precise temperature controls during processing

- Multi-stage filtration systems

5. Quality Control Measures

- X-ray fluorescence (XRF) testing

- Mass spectrometry verification

- Independent assay certification

Why Choose Professional Refining?

- Our facility recovers 98%+ of available precious metals

- Environmentally responsible processing

- Transparent reporting with exact yield figures

For the most efficient precious metal recovery from your spark plugs, trust Dingfeng Precious Metals Recycling's scientific approach.