Platinum rhodium wire recycling_ Platinum rhodium alloy recycling_ Precious metal recycling manufacturers

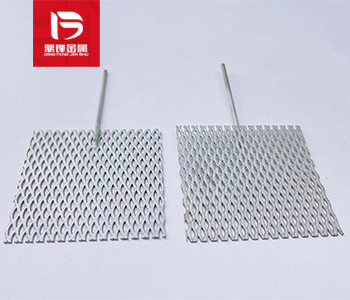

Platinum-rhodium wire is a thin wire composed of two precious metal alloys, platinum and rhodium, which has the characteristics of high-temperature oxidation resistance, corrosion resistance, and excellent electrical conductivity. It is widely used in various high-temperature equipment, electronic components, chemical catalysts and other fields. Waste platinum-rhodium wire is one of the sources of rhodium-containing waste recycling. The sources of rhodium-containing waste recycling include rhodium block recycling, rhodium slag recycling, rhodium water recycling, rhodium slurry recycling, rhodium rod recycling, platinum-rhodium leak plate recycling, etc.

Product Details

Platinum rhodium wire is a fine wire composed of two precious metal alloys, platinum and rhodium, with characteristics such as high-temperature oxidation resistance, corrosion resistance, and excellent conductivity. It is widely used in various high-temperature equipment, electronic components, chemical catalysts, and other fields.

The production method of platinum rhodium wire can be achieved through the following steps:

1. Raw material preparation: The production of platinum rhodium wire requires the preparation of high-purity platinum and rhodium metal powders as raw materials. These metal powders undergo multiple processes such as calcination and sieving to remove impurities, ensuring that the resulting platinum rhodium wire has high purity and excellent performance.

2. Mixing and homogenization: Mix the prepared platinum and rhodium metal powder in a certain proportion to obtain the required alloy composition. During the mixing process, homogenization treatment is required to ensure uniform distribution of metal powder and sufficient mixing of alloy components.

3. Smelting: Put the uniformly mixed metal powder into a high-temperature smelting furnace for smelting. During the smelting process, the metal powder is heated to a high temperature to melt and mix evenly. Under appropriate conditions, platinum and rhodium form alloy solutions.

4. Ingot preparation: The alloy solution after smelting is poured into the mold, cooled and solidified to obtain the ingot. The composition of the ingot is the same as that of the required platinum rhodium wire.

5. Forging and drawing: Forging and processing the ingot to form a bar. During the forging process, the density and ductility of the metal are increased by gradually reducing the cross-sectional area. Next, the forged bars are fed into the wire drawing machine for wire drawing. During the wire drawing process, the rod is gradually elongated and refined, ultimately obtaining the required diameter of platinum rhodium wire.

6. Cleaning and treatment: After the production of platinum rhodium wire is completed, it needs to be cleaned and treated. During the cleaning process, chemical solutions or mechanical methods are used to remove surface dirt and impurities, ensuring the cleanliness and purity of the wire material. During the processing, methods such as heat treatment and annealing can be used to further improve the mechanical and electrical properties of the wire.

Waste platinum rhodium wire is one of the sources of rhodium containing waste recycling, which includes rhodium block recycling, rhodium slag recycling, rhodium water recycling, rhodium slurry recycling, rhodium rod recycling, and platinum rhodium leakage plate recycling. If you have any demand for rhodium containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory. There are no intermediaries to earn price differences, and professional technical teams and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.