Closed-Loop Catalyst Solutions: Dingfeng Sustainable Metals Recovery Program

Industrial catalyst waste contains valuable platinum group metals (PGMs) that traditional mining extracts at high environmental cost.

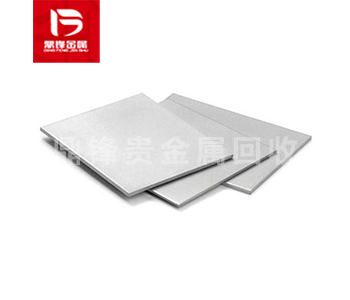

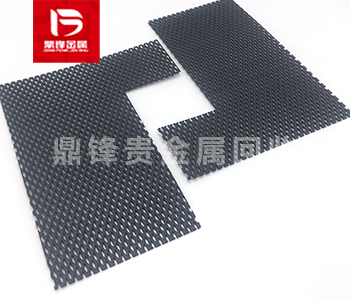

Product Details

The Environmental Imperative for Catalyst Recycling

Industrial catalyst waste contains valuable platinum group metals (PGMs) that traditional mining extracts at high environmental cost:

Virgin PGM mining consumes 10 times more energy than recycling

Generates 40 times more CO2 emissions

Requires extensive natural resource extraction

Dingfeng’s closed-loop system recovers over 95% of PGMs while supporting UN Sustainable Development Goal 12 and EU Green Deal compliance.

Dingfeng’s Sustainable Recovery Process

1. Eco-Efficient Metal Extraction

Hydrometallurgical methods replace energy-intensive smelting

Closed-loop water treatment eliminates liquid waste

99.9% pure output meeting LBMA standards

2. Low-Carbon Operations

Optimized global collection routes minimize transport emissions

Bulk processing reduces per-unit energy consumption

3. Certified Circular Solutions

Recovered metals reintegrated into supply chains

ISO 14001 and R2v3 certified facilities

Environmental Impact Comparison

Metric Virgin Mining Dingfeng Recycling

Energy (MJ/kg) 200,000 15,000

CO2 Emissions (kg) 10,000 250

Water Use (L/kg) 150,000 5,000

Data source: 2023 Life Cycle Assessment

Industry Applications

Petrochemical (FCC catalysts)

Pharmaceutical (hydrogenation catalysts)

Automotive (fuel cell catalysts)

Implement Your Recycling Program

Complimentary waste audit for spent catalysts

ESG performance reporting

Legal compliance documentation

Contact Dingfeng Sustainability Team:Email:dfpmr5719@dfpmr.com. WhatsApp:+8613760175719