Ruthenium target material recycling_ Recovery of sputtering ruthenium target material_ Precious metal recycling manufacturers

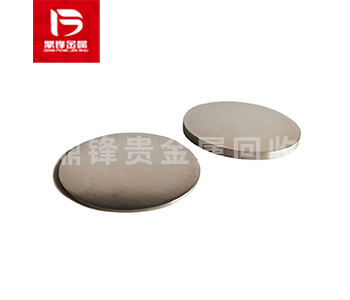

Ruthenium targets are mainly made of high-purity ruthenium metal, and the purity is usually required to be above 99.99%. High-purity ruthenium metal has many good physical and chemical properties, such as high melting point, corrosion resistance, good thermal stability, etc. Ruthenium metal is a silvery-white precious metal with high density and hardness, low thermal expansion coefficient, and a melting point of up to 3180 degrees Celsius. The recycling of waste ruthenium targets is one of the recycling of rare precious metal targets. The recycling of rare precious metal targets also includes silver target recycling, germanium target recycling, platinum target recycling, gold target recycling, indium target recycling, iridium target recycling, and tantalum target recycling.

Product Details

1、 Composition and properties

Ruthenium targets are mainly made of high-purity ruthenium metal, usually with a purity requirement of over 99.99%. High purity ruthenium metal has many good physical and chemical properties, such as high melting point, corrosion resistance, and good thermal stability. Ruthenium metal is a silver white precious metal with high density and hardness, low coefficient of thermal expansion, and a melting point of up to 3180 degrees Celsius.

2、 Preparation method

The commonly used method for preparing ruthenium targets is metallurgical process, which usually includes the following steps: 1. Raw material preparation: Select high-purity ruthenium metal powder as the raw material, requiring fine and uniform powder particles and extremely low impurity content. 2. Mixing and pressing: Mix ruthenium metal powder with a small amount of binder to form a uniform mixture. Then, the mixture is placed in the mold and pressed to obtain a target blank with the required size and shape. 3. Sintering and processing: Place the target material blank at high temperature for sintering, so that the metal particles combine to form dense grains. Then, the billet is processed into the final ruthenium target material through processes such as mechanical processing, cutting, and polishing.

3、 Application field

1. Optical thin films: Ruthenium targets can be used to prepare high-quality optical thin films. Optical thin films are widely used in fields such as solar cells, displays, and optical lenses, with excellent transparency and reflectivity. 2. Conductive thin films: Ruthenium targets can be used to prepare conductive thin films, such as conductive layers in electronic devices such as integrated circuits, flat panel displays, touch screens, etc. Ruthenium targets have excellent conductivity and stability, and can provide reliable current conduction. 3. Ceramic thin films: Ruthenium targets can also be used to prepare ceramic thin films, such as for wear resistant coatings, high-temperature resistant coatings, etc. The high melting point and corrosion resistance of ruthenium targets make the prepared ceramic thin films excellent in durability and performance stability.

The recycling of waste ruthenium targets belongs to one of the rare and precious metal target recycling, including silver target recycling, germanium target recycling, platinum target recycling, gold target recycling, indium target recycling, iridium target recycling, tantalum target recycling, etc. If you have a demand for rare and precious metal target recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.

- Previous:No time

- Next:Recovery of waste liquid containing ruthenium_ Ruthenium wat