Ruthenium slurry recovery_ Recovery of waste containing ruthenium_ Precious metal recycling manufacturers

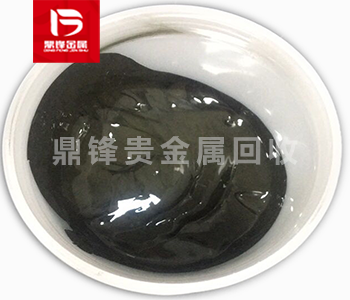

Ruthenium slurry refers to a liquid formed by suspending ruthenium powder in a solvent, which is usually used in catalysts, electronic materials and other high-tech applications. Ruthenium is a precious transition metal with good corrosion resistance, high melting point and hardness. It has good catalytic activity in chemical reactions, especially in redox reactions and organic synthesis. Waste ruthenium slurry is one of the recycling channels for ruthenium-containing waste. Other recycling channels for ruthenium-containing waste include ruthenium water recycling, ruthenium alloy recycling, ruthenium slag recycling, ruthenium powder recycling, ruthenium iridium mesh recycling, ruthenium wire recycling, ruthenium block recycling, etc.

Product Details

Ruthenium slurry refers to a liquid formed by suspending ruthenium powder in a solvent, typically used in catalysts, electronic materials, and other high-tech applications. Ruthenium is a valuable transition metal with good corrosion resistance, high melting point, and hardness. It has good catalytic activity in chemical reactions, especially in Redox and organic synthesis. The preparation process of ruthenium slurry requires careful control of the dispersion and stability of the powder to ensure the preparation of high-quality ruthenium slurry.

The preparation of ruthenium slurry usually includes the following steps: 1. Raw material preparation: Firstly, the required ruthenium and other metal elements need to be prepared. These metals can exist in powder or block form and undergo pre-treatment as needed, such as crushing or melting. 2. Alloy preparation: Mix the pre treated metal raw materials together in a certain proportion. Mixing can be carried out through mechanical stirring, ball milling, and other methods to ensure uniform dispersion of various metals. 3. Solvent selection: Select an appropriate solvent based on the required viscosity and solubility requirements. Commonly used solvents include organic solvents, water, and alcohol. 4. Mixing of solvent and raw materials: Suspend the alloy raw materials in the solvent and thoroughly mix and stir until a uniform slurry is formed. 5. Additives: As needed, auxiliary agents such as surfactants, dispersants, or stabilizers can be added to improve the dispersibility and stability of ruthenium slurry. 6. Further treatment: According to specific needs, the ruthenium slurry can be further treated through steps such as filtration, centrifugation, and drying to obtain the required properties and forms.

Waste ruthenium slurry is one of the recycling channels for ruthenium containing waste, including ruthenium water recycling, ruthenium alloy recycling, ruthenium slag recycling, ruthenium powder recycling, ruthenium iridium mesh recycling, ruthenium wire recycling, ruthenium block recycling, etc. If you have any demand for the recycling of ruthenium containing waste, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has independent recycling and refining factories without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.