Ruthenium alloy recycling_ Recovery of ruthenium iridium alloy_ Precious metal recycling manufacturers

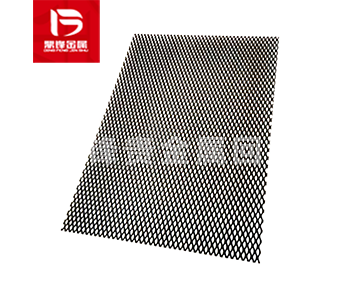

Ruthenium-iridium alloy is an alloy material composed of two precious metals, ruthenium and iridium, with excellent chemical stability, high melting point and good mechanical properties. This alloy is usually expressed in the ratio of ruthenium to iridium. For example, the common alloy composition is 90% ruthenium and 10% iridium or 80% ruthenium and 20% iridium. Waste ruthenium-iridium alloy is one of the recycling sources of ruthenium-containing waste. Other sources of recycling of ruthenium-containing waste include ruthenium alloy recycling, ruthenium-iridium mesh recycling, ruthenium slag recycling, ruthenium sheet recycling, ruthenium slurry recycling, ruthenium tube recycling, ruthenium sheet mesh recycling, etc.

Product Details

Ruthenium iridium alloy is an alloy material composed of two precious metals, ruthenium and iridium, with excellent chemical stability, high melting point, and good mechanical properties. This type of alloy is usually represented by the ratio of ruthenium to iridium, for example, common alloy compositions include 90% ruthenium and 10% iridium or 80% ruthenium and 20% iridium. Ruthenium iridium alloys have wide applications in many fields, especially in high-temperature and corrosive environments, such as aerospace, chemical, petroleum, and nuclear industries. Its excellent corrosion resistance makes it an ideal material for making nozzles, catalysts, electrodes, furnace parts, and other equipment that requires high temperature and corrosion resistance.

The process of making ruthenium iridium alloy is relatively complex and can generally be completed through the following steps:

1. Raw material preparation: Firstly, high-purity ruthenium and iridium metals need to be prepared as raw materials. These metals typically exist in the form of powders or blocks.

2. Mixing: Mix pre weighed ruthenium and iridium metal powders together in a certain proportion. The purpose of mixing is to ensure that the two metals are evenly distributed, forming a uniform alloy structure.

3. Sintering: Place the mixed metal powder into a high-temperature furnace for sintering treatment. Sintering refers to heating metal powder at a certain temperature to combine its particles and form a dense alloy billet.

4. Metallurgical treatment: The sintered alloy billet may still have some impurities and pores, and metallurgical treatment is needed to improve the purity and uniformity of the alloy. Metallurgical treatment can include processes such as heat treatment, rolling, forging, etc.

5. Forming processing: After metallurgical treatment, the ruthenium iridium alloy blank can be formed through various processing methods, such as casting, forging, rolling, stretching, etc. These processing techniques can be selected based on specific needs and applications.

6. Precision machining and surface treatment: The formed ruthenium iridium alloy can undergo precision machining, such as cutting, turning, drilling, etc., to meet specific size and shape requirements. In addition, surface treatments such as polishing and pickling can also be carried out to improve the surface quality and glossiness of the alloy.

Waste ruthenium iridium alloy is one of the recycling sources of ruthenium containing waste. The recycling sources of ruthenium containing waste include ruthenium alloy recycling, ruthenium iridium mesh recycling, ruthenium slag recycling, ruthenium sheet recycling, ruthenium slurry recycling, ruthenium tube recycling, ruthenium sheet mesh recycling, etc. If you have any demand for the recycling of ruthenium containing waste, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has independent recycling and refining factories without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.