Ruthenium carbon recovery_ Recovery and Recycling Method of Ruthenium Carbon Catalyst

The necessity of recovering ruthenium carbon catalysts:1. Recycling reduces the demand for mining and producing new ruthenium, which is an expensive and energy intensive process.2. Recycling helps red

The necessity of recovering ruthenium carbon catalysts:

1. Recycling reduces the demand for mining and producing new ruthenium, which is an expensive and energy intensive process.

2. Recycling helps reduce waste, as it keeps the catalyst circulating rather than ultimately entering landfills.

3. Recycling ruthenium carbon catalysts can recycle ruthenium catalysts and reduce production costs. Finally, recycling can help reduce the environmental pollution caused by the extraction and manufacturing of new ruthenium.

Recovery and extraction method of ruthenium carbon catalyst:

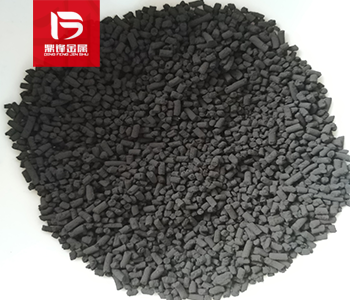

The recovery and refining of ruthenium carbon catalysts are important processes in many industries. Due to its high selectivity and ability to shorten reaction time, it is widely used. In order to produce the required chemicals and compounds, their recovery and refining are necessary. The process starts with collecting and classifying waste catalyst materials. Then, before the ruthenium is separated from the carbon carrier, any pollutants are removed from the material. The first step in the recycling and refining process is to collect and classify waste catalyst materials. This material is usually classified based on its composition and checked for any pollutants. Once the material is classified, it is then heated to a temperature of 800-1000C to remove any remaining organic material. This heating process releases ruthenium from the carbon carrier and allows for the separation of the two components. After the heating step, the next step in the recovery and refining process is to separate the ruthenium from the carbon carrier. This is usually accomplished through a series of leaching and precipitation steps. During this process, ruthenium is extracted from the carbon carrier and precipitated in solid form. This solid is then filtered, washed, and dried for further processing. Then, various technologies are used to further treat and purify the recovered ruthenium.

These technologies can include distillation, electrolysis and other Chemical process. The goal of these processes is to ensure that ruthenium meets the required specifications. Once the ruthenium is purified, it is then tested and analyzed to ensure that it meets the usage standards. This process is essential in order to produce the required products and compounds.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;