Tantalum silicide recovery_ Tantalum disilicide recovery_ Rare metal recycling manufacturers

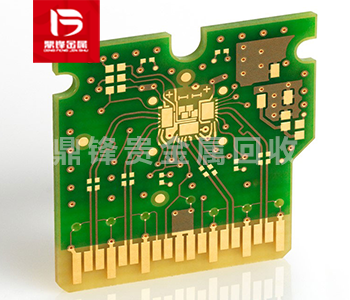

Tantalum silicide is an alloy material composed of tantalum and silicon elements, with the chemical formula TaSi2. Tantalum silicide has excellent properties such as high temperature stability, corrosion resistance and mechanical strength, so it is widely used in electronics, aerospace and energy. Waste tantalum silicide is one of the sources of tantalum waste recycling. Tantalum waste recycling also includes tantalum silicide recycling, tantalum oxide recycling, tantalum lithium acid recycling, tantalum carbide recycling, metal tantalum recycling, tantalum nitride recycling, tantalum powder recycling, tantalum capacitor recycling, etc.

Product Details

Tantalum silicide is an alloy material composed of tantalum and silicon elements, with the chemical formula TaSi2. Tantalum silicide has excellent properties such as high-temperature stability, corrosion resistance, and mechanical strength, making it widely used in fields such as electronics, aerospace, and energy.

The preparation of tantalum silicide can usually be achieved through chemical vapor deposition (CVD) or mechanical alloying methods:

1. Chemical Vapor Deposition (CVD): This method involves introducing precursors of silicon and tantalum into a reaction chamber and conducting chemical reactions at high temperatures. In the CVD process, silicon chloride (SiCl4) and tantalum chloride (TaCl5) are often used as precursors for silicon and tantalum. The reaction temperature is usually between 800C and 1200C, and using the principle of thermal decomposition, silicon and tantalum elements react with hydrogen gas to generate tantalum silicide. The Chemical equation of the reaction is as follows: 3SiCl4+2TaCl5+10H2 2TaSi2+12HCl+3SiH4

After the reaction is completed, tantalum silicide can be collected and extracted from the reaction chamber, and after subsequent processing and processing, the desired shape and size can be obtained.

2. Mechanical alloying: This method involves mixing tantalum powder with silicon powder and reacting under the action of mechanical forces such as high-energy ball milling. During the mechanical alloying process, tantalum and silicon particles are subjected to high-energy ball milling mechanical forces for collision and friction, leading to atomic diffusion and chemical reactions. After a certain period of ball milling, the atoms of tantalum and silicon gradually mix and form tantalum silicide. Finally, the required tantalum silicide material can be obtained through subsequent heat treatment and processing steps.

Waste tantalum silicide is one of the sources of tantalum waste recovery. The recovery of tantalum waste includes tantalum silicide recovery, tantalum oxide recovery, tantalum lithium oxide recovery, Tantalum carbide recovery, metal tantalum recovery, tantalum nitride recovery, tantalum powder recovery, tantalum capacitor recovery, etc. If you have any demand for tantalum containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.