Iridium target material recycling_ Recovery of sputtering iridium target material_ Precious metal recycling manufacturers

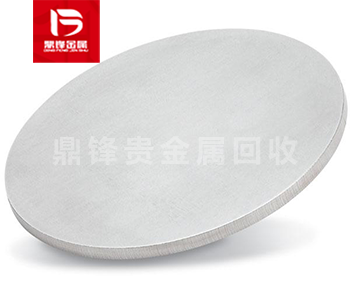

Iridium target is an important material used in the manufacture of precision electronic devices and scientific research. Iridium (Ir) is a rare metal with high density, high melting point and good chemical stability, making it an ideal choice for the manufacture of high-performance electronic devices. Iridium targets are often used in the manufacture of semiconductor devices, display screens, optoelectronic devices, and nuclear energy research. The recycling of waste sputtering iridium targets is one of the rare precious metal target recycling. The recycling of rare precious metal targets also includes silver target recycling, ruthenium target recycling, platinum target recycling, gold target recycling, indium target recycling, germanium target recycling, tantalum target recycling, etc.

Product Details

Iridium target material is an important material used for manufacturing precision electronic devices and scientific research. Iridium (Ir) is a rare metal with high density, high melting point, and good chemical stability, making it an ideal choice for manufacturing high-performance electronic devices. Iridium targets are often used in the manufacturing of semiconductor devices, display screens, optoelectronic devices, and nuclear energy research.

The production process of iridium targets is usually divided into the following steps:

1. Preparation of raw materials: The first step in producing iridium targets is to prepare high-purity iridium metal raw materials. Common sources of raw materials include the recovery of iridium ore and waste devices. These raw materials require processes such as ore beneficiation, chemical treatment, and smelting to obtain high-purity iridium metal.

2. Casting: Casting is the process of melting and pouring iridium metal into a specific shaped mold. This can be achieved through methods such as arc melting, vacuum arc melting, or electron beam melting. During the casting process, it is necessary to control the melting temperature and cooling rate to ensure the uniformity and density of iridium metal.

3. Hot working: The cast iridium billet needs to be further improved by Hot working to further improve its performance and shape. Common Hot working methods include forging, rolling and stretching. These processes can make the grain structure of iridium metal more dense and adjust the hardness and shape of the material.

4. Surface treatment: In order to improve the service life and performance of iridium targets, surface treatment is often required. This includes mechanical polishing, Electropolishing and chemical polishing to remove impurities and defects on the surface and obtain a smooth surface.

5. Testing and quality control: Strict testing and quality control are required at each stage of the iridium target preparation process. Common detection methods include metallographic observation, chemical analysis, and physical performance testing. These tests can ensure that the iridium target meets the expected performance and specification requirements.

The recycling of waste sputtering iridium targets belongs to one of the rare and precious metal target recycling, including silver target recycling, ruthenium target recycling, platinum target recycling, gold target recycling, indium target recycling, germanium target recycling, tantalum target recycling, etc. If you have a demand for rare and precious metal target recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.

- Previous:No time

- Next:Chloroiridium acid recovery_ Iridium catalyst recovery_ Prec