Platinum iridium electrode recovery_ Platinum iridium alloy recycling_ Precious metal recycling manufacturers

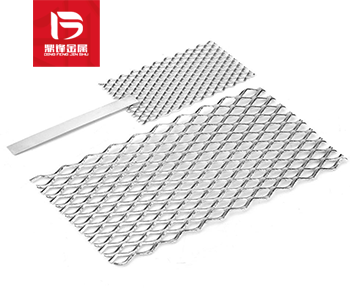

Platinum-iridium electrode is a common electrochemical electrode composed of two metals, platinum and iridium. This electrode is widely used in various scientific research and industrial fields, especially in electrochemical reactions and corrosion research. Platinum-iridium electrode has good chemical stability, electrical conductivity and corrosion resistance, so it is widely recognized as an efficient and reliable electrode material. Waste platinum-iridium electrode is one of the important sources of iridium-containing waste recycling. Iridium-containing waste recycling also includes iridium-plated titanium plate recycling, iridium rod recycling, iridium-rhodium alloy recycling, iridium block recycling, iridium tube recycling, iridium crucible recycling, iridium titanium mesh recycling, and iridium gold recycling.

Product Details

Platinum iridium electrode is a common electrochemical electrode composed of two metals: platinum and iridium. This type of electrode is widely used in various scientific research and industrial fields, especially in electrochemical reactions and corrosion research. Platinum iridium electrodes have excellent chemical stability, conductivity, and corrosion resistance, making them widely recognized as efficient and reliable electrode materials.

The production process of platinum iridium electrodes is relatively complex and involves multiple steps. The following is a detailed overview of the production process: 1. Raw material preparation: The first step in producing platinum iridium electrodes is to prepare the required raw materials, namely platinum and iridium powder. These powders can usually be purchased from suppliers. 2. Mixing: Mix platinum and iridium powder in a certain proportion. The purpose of mixing is to evenly distribute the two metals to achieve better electrode performance. 3. Pressing: Place the mixed metal powder into the mold and use high pressure to press it into the desired shape of the electrode. This step is commonly referred to as suppression. 4. Sintering: Place the pressed electrode into a high-temperature furnace for sintering. The purpose of sintering is to combine metal powder into a sturdy electrode material through heating. During the sintering process, the particles between the metal powders will bind together and form a sturdy electrode structure. 5. Grinding and polishing: The sintered electrode is usually not perfectly smooth and requires grinding and polishing to obtain a smooth surface. This can be achieved by using grinding tools and polishing agents. 6. Cleaning: Cleaning is a very important step to remove impurities and dirt that may adhere to the electrode surface during the manufacturing process. Common cleaning methods include solvent and Ultrasonic cleaning. 7. Oxidation: Platinum iridium electrodes often require oxidation treatment to improve their electrode activity and stability. The oxidation process can be carried out by exposing the electrode to an oxidant solution or by electrochemical methods.

Waste platinum iridium electrodes are one of the important sources of iridium containing waste recycling. Iridium containing waste recycling also includes iridium plating titanium plate recycling, iridium rod recycling, iridium rhodium alloy recycling, iridium block recycling, iridium tube recycling, iridium crucible recycling, iridium titanium mesh recycling, and iridium gold recycling. If you have any demand for iridium containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.