Recovery of Iridium Rhodium Alloy_ Iridium alloy recycling price_ Precious metal recycling and refining manufacturers

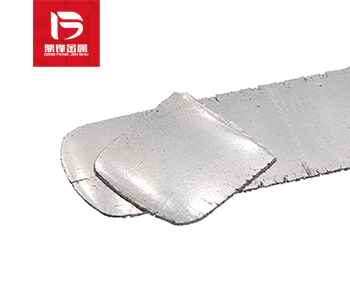

Iridium-rhodium alloy is an alloy composed of two rare metal elements, iridium (Ir) and rhodium (Rh). They belong to the platinum group metals in the periodic table and have many similar properties. Iridium-rhodium alloy combines the advantages of these two metals. Scrap iridium-rhodium alloy is one of the sources of iridium-containing waste recycling. Iridium-containing waste recycling also includes iridium-plated titanium plate recycling, iridium powder recycling, iridium gold recycling, iridium block recycling, iridium tube recycling, iridium crucible recycling, iridium wire recycling, and iridium pellet recycling. If you have any iridium-containing waste recycling needs, please call our 24-hour service hotline.

Product Details

1、 Basic characteristics of iridium rhodium alloy

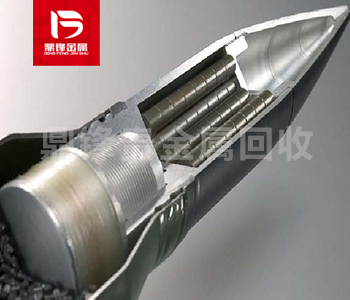

Iridium rhodium alloy is an alloy composed of two rare metal elements, iridium (Ir) and rhodium (Rh). They belong to Platinum group in the periodic table and have many similar properties. Iridium rhodium alloy combines the advantages of these two metals and exhibits the following characteristics: 1. High melting point: Iridium rhodium alloy has a very high melting point, which can reach over 2200 ℃, making it exhibit superior stability in high-temperature environments. 2. Corrosion resistance: Iridium rhodium alloy has excellent corrosion resistance and high stability to most acids, alkalis, and chlorides, making it suitable for harsh chemical environments. 3. Wear resistance: Iridium rhodium alloy has good wear resistance, characterized by low friction coefficient and high wear resistance, suitable for high load and high-speed sports occasions. 4. Oxidation resistance: At high temperatures, iridium rhodium alloy has excellent oxidation resistance, which can withstand oxidation environments up to 2000 ℃, helping to maintain the stability and integrity of the material.

2、 Preparation method of iridium rhodium alloy

The preparation of iridium rhodium alloys mainly includes the following methods: 1. Melting method: By high-temperature melting, iridium and rhodium are fused together, and then cooled and solidified to form iridium rhodium alloys. This method is simple and cost-effective, but it has certain limitations on the preparation of high-purity alloys. 2. Powder metallurgy: mix the iridium and rhodium metal powders evenly, and then sinter them by hot pressing, Hot isostatic pressing and other methods to form iridium rhodium alloy. This method can obtain alloys with higher purity, but the cost is higher. 3. Electrochemical method: Using iridium and rhodium ions in the electrolyte to form an iridium rhodium alloy layer on the substrate through electrochemical deposition. This method can prepare high-purity iridium rhodium alloy films, which are widely used in fields such as microelectronic devices. 4. Sputtering method: By using magnetron sputtering technology, the atoms of iridium and rhodium targets are sputtered onto the substrate surface in a high vacuum environment, forming an iridium rhodium alloy thin film. This method can obtain alloy thin films with good density and purity, but the cost is relatively high.

Iridium rhodium alloy has become an ideal material for many high-end industrial fields due to its excellent high-temperature performance, corrosion resistance, wear resistance, and oxidation resistance. With the continuous development of science and technology, the application prospects of iridium rhodium alloys will be broader, making greater contributions to the progress of human society. Waste iridium rhodium alloy is one of the sources of iridium containing waste recycling. Iridium containing waste recycling also includes iridium plating titanium plate recycling, iridium powder recycling, iridium gold recycling, iridium block recycling, iridium tube recycling, iridium crucible recycling, iridium wire recycling, and iridium particle recycling. If you have any demand for iridium containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has its own recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.