Iridium Metal Recycling: The Value and Process Behind a Precious Resource

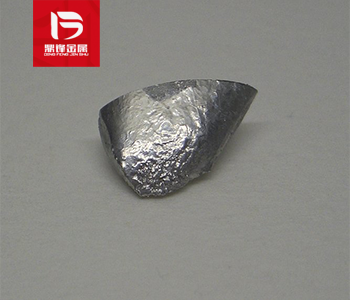

Once the iridium is purified, it is often in the form of a fine powder or small ingots. These can then be sold back to industries that require iridium for manufacturing or further refinement. Recycling iridium is a more cost-effective method compared to mining for new sources of the metal. Given its high price, recycling offers significant economic benefits, especially for companies that use large quantities of iridium in their products.

Product Details

Iridium is a rare and valuable metal, known for its remarkable resistance to corrosion and high melting point. This makes it a highly sought-after material in industries like aerospace, electronics, and even medical equipment manufacturing. However, its scarcity means that it is often recycled to meet demand, reducing the need for mining and helping to conserve natural resources. In this article, we explore the process of iridium metal recycling, its importance, and the current recycling prices for those interested in recovering this precious metal.

Iridium is often found in small quantities within the Earth's crust, which makes it one of the rarest metals. Despite its scarcity, the demand for iridium continues to rise due to its unique properties. It is used in spark plugs, catalytic converters, and various high-tech applications. As industries grow, so does the need for efficient recycling programs to recover iridium from used components. The process of recycling iridium is not only economically beneficial but also environmentally friendly, as it reduces the need to extract the metal from the Earth, which can be a costly and environmentally harmful process.

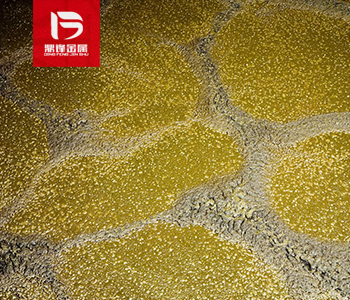

The recycling process typically begins by collecting used iridium from industrial and commercial sources. This might include old electronics, medical devices, automotive parts, and other equipment containing iridium. Once the material is gathered, it is sent to specialized recycling facilities where it undergoes a series of steps to extract the metal. The first step is often to remove any non-metallic impurities, such as plastics, which are commonly found in electronics. The remaining metal is then purified, usually through chemical processes like electrolysis or high-temperature heating.

Once the iridium is purified, it is often in the form of a fine powder or small ingots. These can then be sold back to industries that require iridium for manufacturing or further refinement. Recycling iridium is a more cost-effective method compared to mining for new sources of the metal. Given its high price, recycling offers significant economic benefits, especially for companies that use large quantities of iridium in their products.

Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price.

Email us with pictures at dfpmr5719@dfpmr.com or send us on whatsapp at +8613760175719 to discuss your materials. We provide professional evaluations of industrial precious metal-bearing scrap and estimates of precious metal content.