Crude indium recovery_ Refined indium recycling price_ Precious metal recycling and refining manufacturers

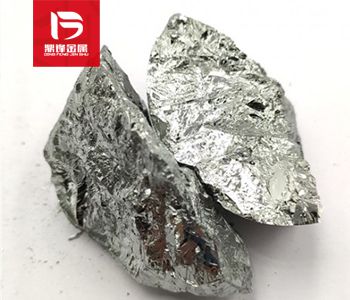

Crude indium refers to indium ore or indium-containing waste, and refined indium is the product of refining and removing impurities from crude indium. Indium can be called the "vitamin of alloy". Indium alloy can be used as brazing material. Indium is a new important additive element of lead-free solder. The development trend of lead-free solder in the world is conducive to the application of indium brazing material. Utilizing the low melting point of indium alloy, it can also be made into a special alloy, which is used in the circuit breaker protection device of the fire protection system and the thermal control device of the automatic control system; the bearing alloy made by adding a small amount of indium is 4-5 times the service life of the general bearing alloy. Both are sources of indium waste recycling. The sources of indium waste recycling include indium slime recycling, indium slag recycling, indium sheet recycling, indium grain recycling, indium wire recycling, indium ingot recycling, etc.

Product Details

Crude indium refers to indium ore or indium containing waste, while refined indium is the product of processing and refining crude indium to remove impurities. Indium can be called the "vitamin of alloys", and indium alloys can be used as solder. Indium is a new and important additive element in lead-free solder, and the development trend of lead-free solder in the world is conducive to the application of indium solder. By utilizing the low melting point of indium alloy, special alloys can also be made, which can be used for circuit breaker protection devices in fire protection systems and thermal control devices in automatic control systems; The service life of bearing alloys made with a small amount of indium added is 4-5 times that of general bearing alloys. A new industry centered around information technology has emerged, and indium tin oxide (ITO) is an indispensable key material for various types of flat panel displays. Currently, about 75% of the world's indium is consumed in this area, and there is still great potential in the future. Moreover, with the continuous progress of indium extraction and processing technology, as well as the reduction of production costs, the application of indium continues to expand. Both are sources of indium waste recycling, including indium mud recycling, indium slag recycling, indium sheet recycling, indium particle recycling, indium wire recycling, indium ingot recycling, etc. If you have any demand for indium containing waste recycling, please call our 24-hour service hotline. Dingfeng Precious Metal Recycling and Refining Factory has an independent recycling and refining factory without intermediaries to earn price differences. Our professional technical team and customer service personnel provide one-on-one services to ensure customer privacy during the recycling process.