Rhodium catalyst recovery, exploring rhodium catalyst recovery technology from a professional perspective

Rhodium catalyst is an important catalyst widely used in chemical industry production processes. However, rhodium is a rare and expensive precious metal, so the recovery and reuse of rhodium catalyst

Rhodium catalyst is an important catalyst widely used in chemical industry production processes. However, rhodium is a rare and expensive precious metal, so the recovery and reuse of rhodium catalyst waste has important economic and environmental significance. This article will explore the methods, challenges, and prospects of rhodium catalyst waste recycling from a professional perspective.

1、 Composition and properties of rhodium catalyst waste

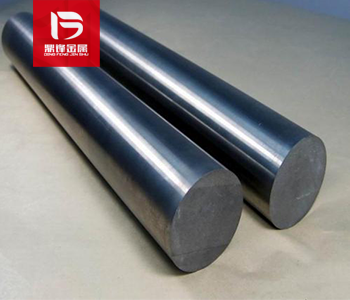

Rhodium catalyst waste is mainly composed of rhodium containing compounds and impurities. Common rhodium catalysts include rhodates, chlororhodates, etc. These catalysts usually act as catalysts and oxidants in chemical reactions, but gradually lose their activity during use, forming waste. Rhodium is a heavy metal element with high melting point, high density, and good chemical stability. Due to its rare and expensive properties, the recycling of rhodium catalyst waste has become very important.

2、 Method for recycling rhodium catalyst waste

1. Physical methods: Physical methods mainly recover rhodium through extraction and separation. Common physical methods include solvent extraction, ion exchange, and distillation. Solvent extraction is a common method of extracting rhodium ions by selecting suitable solvents. Ion exchange achieves the recovery of rhodium by exchanging rhodium ions with other ions. Distillation achieves separation and recovery through the different volatilities between rhodium and other substances.

2. Chemical methods: Chemical methods mainly recover rhodium through chemical reactions. Common chemical methods include reduction, precipitation, and complexation. The reduction method uses a reducing agent to reduce rhodium ions to metallic rhodium, achieving recovery. The precipitation rule is to separate and recover rhodium by adding appropriate precipitants to form a precipitate. The complexation law utilizes a complexing agent to form a complex with rhodium, and achieves recovery through the characteristics of the complex.

3. Biological method: Biological method is an emerging recycling method that utilizes microorganisms or biomaterials to recover rhodium. This method has the advantages of being environmentally friendly, efficient, and sustainable. At present, some microorganisms have been found to have the ability to reduce rhodium ions and can be used for the recovery of rhodium catalyst waste.

3、 The Challenge of Rhodium Catalyst Waste Recycling

The recovery of rhodium catalyst waste faces some challenges. Firstly, the composition of rhodium catalyst waste is complex, and there may be other precious metals and impurities present, which require effective separation and extraction through appropriate methods. Secondly, rhodium is a rare and expensive metal, and the recycling process requires a high level of technical and equipment support to ensure recycling efficiency and quality. In addition, some recycling methods may have a certain impact on the environment and require consideration of environmental protection and safety during the recycling process.

4、 Prospects for the recovery of rhodium catalyst waste

The recovery of rhodium catalyst waste has broad prospects. With the increasing demand for rare metal resources and the increasing awareness of environmental protection, the recycling and reuse of rhodium catalyst waste will become an important development direction. New recycling technologies and methods will continue to emerge, improving recycling efficiency and quality. Biological methods as a green and sustainable recycling method will receive more attention and research. In addition, through reasonable recycling and reuse, the demand for rhodium ore can be reduced, production costs can be reduced, and sustainable resource utilization can be achieved.

The recycling of rhodium catalyst waste is an important and challenging task. Through various methods such as physics, chemistry, and biology, rhodium can be recovered and reused. However, further research and technological improvements are still needed to improve recycling efficiency, reduce costs, and ensure environmental friendliness. The development prospects of rhodium catalyst waste recycling are broad and will play an important role in resource utilization and environmental protection. We look forward to continuous innovation and breakthroughs in this field in the future.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;

<img style="width:100%" title="Gold, silver, palladium, platinum and rhodium waste recycling