The Economic Advantages of Rhodium Recycling for Industries

Rhodium is one of the most valuable and rare precious metals on earth, widely used in industries for its superior catalytic performance, corrosion resistance, and thermal stability. Its critical applications in automotive, chemical, and electronic manufacturing make it a strategic metal for global industry. However, the scarcity of rhodium and the high cost of mining have made recycling not just a sustainable practice, but also a powerful economic strategy.

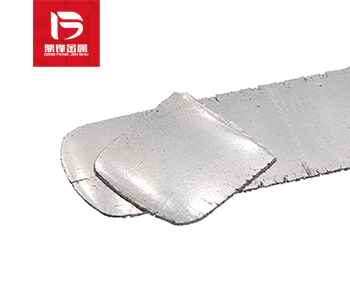

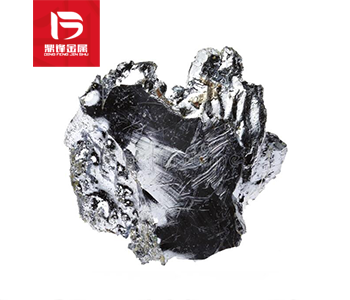

Product Details

Rhodium is one of the most valuable and rare precious metals on earth, widely used in industries for its superior catalytic performance, corrosion resistance, and thermal stability. Its critical applications in automotive, chemical, and electronic manufacturing make it a strategic metal for global industry. However, the scarcity of rhodium and the high cost of mining have made recycling not just a sustainable practice, but also a powerful economic strategy.

At Dingfeng Precious Metals, we specialize in recovering and refining rhodium from industrial waste and used materials. Our professional recycling solutions enable industries to maximize economic returns, reduce raw material costs, and secure long-term resource stability.

The High Market Value of Rhodium

Rhodium’s price per gram is often many times higher than that of gold or platinum. This exceptional value is due to its limited natural supply and increasing demand across various industrial sectors. Because rhodium is typically obtained as a by-product of platinum and nickel mining, its production volume is small and closely tied to those industries. As a result, global rhodium supply remains unstable, and prices often fluctuate significantly.

Recycling rhodium from industrial waste, spent catalysts, and scrap materials provides a steady and cost-effective alternative. Instead of purchasing newly mined rhodium at volatile prices, manufacturers can benefit from a consistent source of recycled metal recovered through professional refining processes.

Turning Industrial Waste into Profit

In many industries, valuable rhodium is discarded in the form of used catalysts, chemical residues, plating waste, and electronic scrap. These materials, though considered waste, contain recoverable rhodium that can generate substantial economic returns when properly processed.

At Dingfeng Precious Metals, we help clients transform waste into profit through precise analysis, efficient recovery, and fair valuation. Our advanced refining technologies ensure that the maximum possible rhodium is recovered from each batch, providing clients with transparent financial benefits while reducing waste disposal costs.

Lowering Raw Material and Production Costs

Mining rhodium is energy-intensive and environmentally costly, and purchasing newly mined metal often places a heavy financial burden on manufacturers. Recycling provides an efficient way to reduce production costs by reusing existing rhodium resources.

Recovered rhodium can be reintroduced directly into industrial production processes, including catalytic converter manufacturing, electronics plating, and chemical catalyst fabrication. This closed-loop approach not only reduces raw material expenses but also contributes to more stable and predictable production costs.

Supply Chain Stability and Risk Management

Global rhodium supply is subject to geopolitical, environmental, and market risks. Mining operations are concentrated in a few regions, particularly South Africa and Russia, making the supply chain vulnerable to disruptions. Recycling mitigates these risks by providing a local and reliable source of rhodium that is independent of external uncertainties.

Companies that invest in rhodium recycling strengthen their resource security and minimize exposure to market volatility. By maintaining a steady internal supply of recycled metal, they gain a competitive advantage and ensure long-term business continuity.

Strengthening Corporate Sustainability

Beyond economic returns, rhodium recycling also enhances corporate sustainability. Companies that prioritize recycling demonstrate environmental responsibility and commitment to green manufacturing. This improves corporate image, attracts investors, and meets growing regulatory and consumer demands for sustainable practices.

Sustainability and profitability can coexist, and rhodium recycling is a perfect example of how industries can achieve both.

Dingfeng Precious Metals: Your Trusted Economic Partner in Recycling

With advanced refining technology, global expertise, and a commitment to transparency, Dingfeng Precious Metals provides professional rhodium recycling services to clients worldwide. Our goal is to help industries recover maximum value from their waste while supporting long-term resource sustainability.

We handle all types of rhodium-bearing materials, including spent catalysts, chemical residues, plating baths, and electronic components. Every stage of our process—from collection and analysis to refining and settlement—is designed to ensure efficiency, integrity, and high economic returns for our clients.

Recycling rhodium is more than an environmental necessity; it is a strategic financial decision. By turning industrial waste into valuable resources, Dingfeng Precious Metals helps industries thrive in an era of resource scarcity and environmental awareness.

For professional rhodium recycling services and financial recovery solutions, contact:

Dingfeng Precious Metals

Email: dfpmr5719@dfpmr.com

WhatsApp: +8613760175719