Palladium catalyst recovery: A technical method for recovering palladium catalyst waste

Catalysts are widely used in many industrial processes, but discarded palladium catalysts can pose potential environmental hazards. Therefore, the recovery of palladium catalyst waste has become cruci

Catalysts are widely used in many industrial processes, but discarded palladium catalysts can pose potential environmental hazards. Therefore, the recovery of palladium catalyst waste has become crucial. This article introduces several efficient methods for recovering palladium catalyst waste, which minimize the waste of palladium catalyst waste and protect the environment.

1、 Background of palladium catalyst recovery

Palladium catalyst is a precious catalyst with excellent catalytic performance, which is widely used in industries such as chemical, pharmaceutical, and petroleum. However, palladium catalysts gradually become inactive during use and eventually become waste. These discarded palladium catalysts typically contain high concentrations of palladium, which, if not recycled, will cause serious environmental pollution.

2、 Physical method recycling

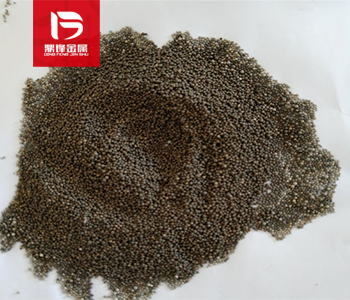

Physical methods are one of the most commonly used techniques for recovering palladium catalyst waste. First, the waste is crushed to make its Granularity suitable for subsequent treatment. Then, palladium in the waste is separated from other impurities through technologies such as magnetic separation, screening, and gravity separation. These methods are based on the physical properties of palladium, such as density and magnetic differences, to achieve the recovery of palladium. The advantages of physical method recycling are simple operation and low cost, but the effect on waste containing complex impurities is poor.

3、 Chemical method recovery

Chemical methods are another commonly used technology for recovering palladium catalyst waste. Among them, leaching method is a common chemical method. This method immerses the waste into a specific solution, causing palladium to react chemically with other components in the waste, forming soluble compounds. Then, the palladium in the solution is separated through steps such as filtration and crystallization. The advantage of chemical recycling is that it can handle complex waste materials, but for situations where the waste contains harmful substances, special attention needs to be paid to the treatment of the waste liquid generated during the treatment process.

4、 High temperature reduction method for recovery

The high-temperature reduction method is an efficient technology for recovering palladium catalyst waste. This method exposes the waste to a high-temperature environment, causing a reduction reaction of palladium compounds to generate pure palladium metal. The high-temperature reduction method can completely decompose organic and inorganic impurities in waste, thereby achieving efficient recovery of palladium. However, due to the high equipment requirements, complex operation, and high cost of high-temperature reduction method, it needs to be carefully considered in practical applications.

5、 Electrochemical method recovery

Electrochemical methods are an emerging technology for recovering palladium catalyst waste. This method utilizes the principle of electrochemistry to deposit pure palladium metal on the electrode surface by electrolysis of waste solution. The advantages of electrochemical method recovery are simple operation, high efficiency, and the ability to achieve high-purity recovery of palladium. However, there are still some challenges in the large-scale application of this technology, such as the treatment of electrolytic solutions and the selection of electrode materials.

The recycling of palladium catalyst waste is crucial for the sustainable utilization of resources and environmental protection. This article introduces several commonly used recovery technologies, including physical methods, chemical methods, high-temperature reduction methods, and electrochemical methods. Different methods have their own advantages and disadvantages, and appropriate technologies should be selected based on the specific situation for the recovery of palladium catalyst waste. In the future, with the advancement of technology and the strengthening of environmental regulations, it is believed that more innovative recycling technologies will emerge, providing better solutions for the recycling of palladium catalyst waste.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;