How to recycle palladium catalysts? Explanation of palladium catalyst waste recycling

Palladium catalyst is a common catalyst widely used in the chemical industry and environmental protection fields. As the usage time increases, the catalyst will gradually fail and the palladium conten

Palladium catalyst is a common catalyst widely used in the chemical industry and environmental protection fields. As the usage time increases, the catalyst will gradually fail and the palladium content in the waste will become higher and higher. Palladium is a precious metal, and the recovery of palladium from waste is crucial for resource utilization and environmental protection. This article will analyze the main steps of recovering palladium catalyst waste.

1、 Waste collection and classification

Firstly, it is necessary to collect the palladium catalyst from the waste. These waste materials may come from chemical plants, laboratories, or other industrial production processes. After collection, classify the waste materials. According to the source and characteristics of waste, it is divided into different categories for subsequent processing.

2、 Palladium waste pretreatment

Palladium catalyst waste typically contains organic matter, inorganic salts, and other impurities. In order to improve recycling efficiency, it is necessary to pre-treat the waste. The goal of pre-treatment is to remove impurities and convert the waste into a form suitable for subsequent treatment.

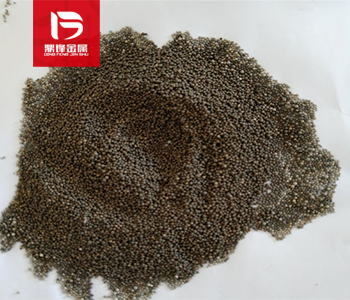

The pre-treatment method can include the following steps: 1. Remove impurities: Use chemical or physical methods to remove organic matter and inorganic salts from the waste. For example, impurities can be removed by Liquid–liquid extraction, ion exchange or adsorption. 2. Waste reduction: If there is palladium in the form of oxides in the waste, reduction treatment is required to reduce it to metallic palladium. Reduction methods can include thermal reduction, reducing agent reduction, or hydrogen reduction. 3. Crushing and screening: Crush and screen the pre treated waste to obtain a uniform particle size for subsequent processing.

3、 Palladium recovery

After the pretreatment, the Committed step of palladium recovery is entered. The main recycling methods are as follows: 1. Solvent extraction: Use organic solvents such as ketones, alcohols, or acids to extract palladium from the waste. The selection of solvents should be determined based on the chemical properties of the waste and the form of palladium. After extraction, palladium is separated from the organic phase by reverse extraction or other methods. 2. Ion exchange: Exchange palladium ions in waste with other ions fixed on ion exchange resins. This is an efficient recovery method that can obtain palladium with high purity. 3. Hydrogen reduction: Expose palladium compounds in waste to a hydrogen atmosphere and convert them into metallic palladium through a reduction reaction. This is a commonly used recycling method suitable for different forms of palladium catalyst waste. 4. Electrochemical recovery: Utilizing electrochemical principles, palladium is electrolyzed from waste. This method has high requirements for the form of palladium in the waste and is suitable for waste materials where palladium exists in the form of ions.

4、 Palladium purification

After palladium recovery, there may still be some impurities that need to be purified to obtain high-purity palladium. There are several commonly used purification methods: 1. Solvent extraction: Use appropriate organic solvents to separate the recovered palladium from impurities. 2. Chlorination treatment: impurities are converted into easily removable chlorides through a chlorination reaction, and then separated by solvent extraction or other methods. 3. Ion exchange: Use ion exchange resin to exchange palladium with other ions and achieve purification.

5、 Finished product processing

The final step is to process the purified palladium as a finished product. This includes morphological transformation of palladium, preparation of alloys, and preparation of catalysts. According to specific application requirements, palladium is further processed to meet different market demands.

The recovery of palladium catalyst waste includes the main steps of waste collection and classification, pretreatment, palladium recovery, palladium purification, and finished product treatment. The selection and order of these steps depend on the characteristics of the waste and the goal of recycling. Through scientific and effective recycling methods, palladium resources in waste can be fully utilized, achieving resource recycling and sustainable environmental development.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;