The entire process of rhodium catalyst recovery and recovery of rhodium catalyst waste

Rhodium catalyst is a catalyst that uses rhodium as the active component. A catalyst is a substance that can accelerate the reaction rate in a chemical reaction without permanent change. Rhodium catal

Rhodium catalyst is a catalyst that uses rhodium as the active component. A catalyst is a substance that can accelerate the reaction rate in a chemical reaction without permanent change. Rhodium catalysts typically exist in the form of rhodium metals or rhodium compounds and can be applied in various chemical reactions and industrial processes. Due to its high value and Scarcity, the recovery of rhodium catalyst waste has become an important environmental protection task. The following will introduce a specific process for recovering rhodium catalyst waste.

Step 1: Waste collection and classification

Rhodium catalyst waste typically comes from industries such as chemical, pharmaceutical, and electronics. Firstly, it is necessary to collect waste materials and classify them. This includes collecting waste from production equipment and classifying and labeling it based on its source, composition, and properties. This helps with subsequent processing and separation steps.

Step 2: Waste pre-treatment

The pre-treatment of waste is to remove impurities and prepare for the next step of treatment. This can include removing dirt, residual organic matter, and other solid impurities attached to the catalyst. A common method is to use solvents for washing and soaking to dissolve or separate impurities. In addition, acid or alkali can also be used to clean and neutralize waste.

Step 3: Crushing of rhodium catalyst waste

After the pre-treatment of the waste is completed, it is necessary to break the waste into smaller particles for better subsequent processing and separation. This can be achieved by using grinding equipment or other appropriate tools. The crushed waste should have appropriate particle size and uniformity.

Step 4: Chemical treatment and dissolution

After crushing, the waste is transferred to a chemical reaction container for chemical treatment and dissolution. In this step, the waste is usually mixed with an appropriate solvent or acidic solution, stirred and heated to promote the dissolution of rhodium ions from the waste to form a solution. The conditions and methods of chemical treatment will vary depending on the characteristics of the waste and the solvents used.

Step 5: Separation and recovery of rhodium ions

Rhodium usually exists in ionic form in solution. In order to separate and recover rhodium ions from solution, various technologies and methods can be used, such as solvent extraction, electrochemical deposition, and membrane separation. Among them, solvent extraction is one of the most commonly used methods. By contacting the solution with an appropriate extractant, rhodium ions will form a complex with the complexing agent in the extractant, thereby achieving the separation and recovery of rhodium.

Step 6: Purification and refining of rhodium

The rhodium complex separated from the solution needs to be purified and refined to improve its purity and quality. This can be achieved through further chemical treatment, filtration, electrolysis, and other separation techniques. These steps will help remove residual impurities and other metal ions, resulting in a purer rhodium.

Step 7: Product Preparation

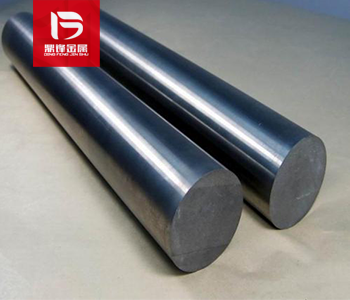

The purified and refined rhodium can be used to prepare various rhodium products. According to specific requirements, rhodium can be prepared into powders, particles, flakes, or other forms of products. This may involve further grinding, forming, and processing steps.

Step 8: Waste disposal and environmental protection

In the process of recycling rhodium catalyst waste, the generated waste and by-products also need to be properly treated to protect the environment and ensure sustainable development. These waste materials may contain toxic or harmful substances and need to be classified, packaged, and stored in accordance with relevant regulations, and appropriate treatment methods such as recycling, neutralization, incineration, or landfill should be taken.

Rhodium catalyst waste recycling is a complex and important task that requires multiple steps such as waste collection, classification, pre-treatment, crushing, chemical treatment, dissolution, ion separation, purification, refining, product preparation, and waste treatment. Through a scientific and efficient recycling process, rhodium resources can be maximally recovered and utilized, reducing their impact on the environment, and improving the sustainable utilization rate of precious metal resources. This helps to protect the environment, conserve resources, and promote sustainable development.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;