Secondary utilization and specific process steps of platinum rhodium wire recycling and extraction

Platinum rhodium wire is a precious metal material, which is widely used in steel, power generation, petroleum, chemical industry, glass fiber, food, glass, pharmacy, ceramics, non-ferrous metals, hea

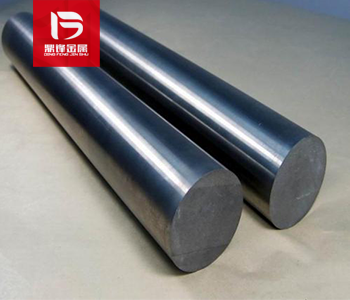

Platinum rhodium wire is a precious metal material, which is widely used in steel, power generation, petroleum, chemical industry, glass fiber, food, glass, pharmacy, ceramics, non-ferrous metals, heat treatment, aerospace, powder metallurgy, carbon, coking, printing and dyeing and almost all other industrial fields. Recycling and refining platinum rhodium wire is an important process that can save resources and reduce environmental impact. This article will introduce the specific steps and processes of recycling waste platinum rhodium wire and the secondary utilization of platinum rhodium wire.

The following are the specific process steps for the recovery and extraction of platinum rhodium wire:

1. Collection and classification: Firstly, it is necessary to collect waste platinum rhodium wire materials from various channels. The main recycling channel for waste platinum rhodium wire is industrial thermocouples. After collection, the materials are classified into different levels and types for subsequent processing.

2. Cleaning and pre-treatment: Clean and pre-treat the collected platinum rhodium wire. The cleaning process can include removing dirt and impurities attached to the silk, such as using solvent immersion, mechanical brushing, and other methods. The purpose of pre-treatment is to remove other metal impurities that may exist, such as dissolving other metals through acid washing or high-temperature treatment.

3. Crushing and grinding: Crush and grind the cleaned and pre treated platinum rhodium wire. This can be achieved by using equipment such as pulverizers and ball mills. The purpose of crushing and grinding is to increase the surface area of the platinum rhodium wire, facilitating subsequent chemical reactions and extraction processes.

4. Chemical reaction: The crushed and ground platinum rhodium wire is reacted with specific chemical reagents. A commonly used reaction is the reaction of platinum rhodium wire with oxygen to produce platinum rhodium oxide. This reaction can be carried out at high temperatures, such as using equipment such as a furnace or reactor. This step aims to convert platinum rhodium into a soluble form in solution.

5. Dissolution and filtration: Dissolve the chemically reacted platinum rhodium wire in an appropriate solvent. Common solvents include hydrochloric acid, nitric acid or Chloroplatinic acid. After dissolution, the solid residues and impurities in the solution are separated by filtration to obtain a pure platinum rhodium solution.

6. Decolorization and precipitation: decolorize the platinum rhodium solution to remove impurities and colors. This can be achieved by adding specific chemical reagents, such as sulfuric acid, Sodium hypochlorite or sodium hydroxide. After decolorization, platinum rhodium is separated from the solution in the form of precipitation by adding a precipitant, such as ammonium chloride or potassium ammonium chloride.

7. Filtering and washing: The precipitated platinum rhodium is filtered and washed to remove impurities and residues. Filtering can be carried out using filter paper or other suitable filtering media. Washing can be carried out using appropriate solvents or water to ensure the purity and quality of platinum rhodium.

8. Drying and processing: Dry the washed platinum rhodium precipitate. Common drying methods include natural air drying or using equipment such as a dryer. After drying, platinum rhodium can be further processed and prepared, such as forming platinum rhodium powder, sheets, or other shapes to meet the needs of different industries.

9. Detection and analysis: Detect and analyze the recovered platinum rhodium to ensure its quality and purity meet the standard requirements. Common analysis methods include mass spectrometry, X-ray diffraction, and chemical analysis. Through testing and analysis, it can be ensured that the quality and composition of platinum rhodium meet market demand.

The above are the general process steps for the recovery and extraction of platinum rhodium wire. The actual operation and equipment may vary depending on different processes and manufacturers, but the overall principles and processes are similar. When recycling and refining platinum rhodium wire, relevant safety operating procedures should be followed, and the sustainability of environmental protection and resource utilization should be ensured.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;