Rhodium water recovery: Process flow for recovering metal rhodium from rhodium wastewater

1、 What is rhodium wastewater?Rhodium wastewater refers to wastewater containing rhodium generated during production, processing, or use. Rhodium is a precious metal commonly used in fields such as ca

1、 What is rhodium wastewater?

Rhodium wastewater refers to wastewater containing rhodium generated during production, processing, or use. Rhodium is a precious metal commonly used in fields such as catalysts, electronic components, and jewelry. In these applications, rhodium may be discharged as wastewater after reacting or dissolving with other substances. The composition and properties of rhodium wastewater vary depending on different industrial processes. It can contain rhodium ions (Rh3+), rhodium compounds, rhodium particles, or other substances related to rhodium. Normally, rhodium wastewater is acidic or neutral, and its pH value may be low. Recycling metal rhodium from rhodium wastewater is an important environmental protection work and also an effective utilization of limited resources. This article will provide a detailed introduction to a process flow for recovering metal rhodium from rhodium wastewater.

2、 Rhodium wastewater recovery process flow

1. Wastewater pretreatment: Firstly, the rhodium wastewater sample is pre-treated to remove suspended solids and particulate matter. This can be achieved through physical methods such as filtration or precipitation. Filtering wastewater samples through filters can effectively remove impurities and improve the effectiveness and stability of subsequent treatment steps.

2. Acid-base neutralization: Rhodium wastewater is usually acidic, so it needs to be neutralized to neutral or alkaline for subsequent treatment. Use acid-base neutralization device, gradually add alkaline chemicals (such as sodium hydroxide or potassium hydroxide) to neutralize wastewater. During the process, it is necessary to control the changes in pH value to ensure that the neutralization degree of the wastewater is appropriate and not excessively alkaline or acidified.

3. Sedimentation treatment: Once the wastewater is neutralized to neutral or alkaline, rhodium is precipitated from the wastewater in the form of precipitates. In order to promote the precipitation process of rhodium, chemical agents such as ammonium chloride, sodium chloride or Iron(III) chloride are added into the precipitation tank. These precipitants react with rhodium ions in wastewater to form insoluble rhodium precipitates. Subsequently, the precipitate is separated by filtration.

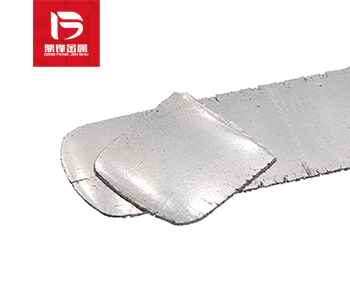

4. Sediment treatment: Dry or distill the precipitate to obtain purer rhodium metal. This step can be achieved through a distillation device, which removes impurities from the precipitate and improves the purity of rhodium metal. The specific drying or distillation operation needs to be carried out according to the actual situation and ensure the safety of the operation.

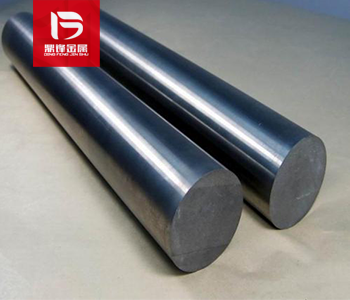

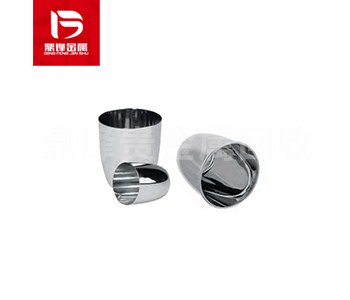

5. Electrolytic recovery: The obtained pure metal rhodium is used as an anode and placed in an electrolytic cell for electrolytic recovery together with an appropriate electrolyte. The commonly used electrolyte is a solution containing rhodium salts. During the electrolysis process, the metal rhodium anode is oxidized to rhodium ions, while on the cathode, rhodium ions are reduced to metal rhodium and deposited on the cathode. By controlling current density and electrolysis time, the recovery rate and purity of rhodium metal can be ensured.

6. Collection and Treatment of Sediments: Finally, collect and treat the metal rhodium deposits in the electrolytic cell. Collect the metal rhodium deposited on the cathode and undergo necessary processing steps such as washing, drying, and smelting to obtain the final metal rhodium product.

It should be noted that specific process parameters and conditions may vary depending on the composition and requirements of the wastewater. In practical applications, it is necessary to optimize and adjust the process according to specific circumstances to ensure the recovery efficiency and product quality of rhodium metal, and meet safety and environmental requirements.

The recycling of rhodium not only helps to reduce resource waste and environmental pollution, but also meets the market demand for rhodium, promoting sustainable development and the realization of a circular economy. Therefore, the process of recovering metal rhodium from rhodium wastewater is of great significance and has brought positive impacts on environmental protection and economy.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;