Rhodium plating recovery: detailed introduction to the process technology of electrolytic rhodium recovery

Electrolytic rhodium technology is a method of extracting rhodium from rhodium ore using the principle of electrolysis. Rhodium is a precious Platinum group with high Scarcity and market value. It has

Electrolytic rhodium technology is a method of extracting rhodium from rhodium ore using the principle of electrolysis. Rhodium is a precious Platinum group with high Scarcity and market value. It has a wide range of applications in industrial production, such as catalysts, electrode materials, medical devices, etc. This article will provide a detailed introduction to the process flow, advantages and disadvantages, and application of electrolytic rhodium technology.

1、 Process flow

The process flow of electrolytic rhodium technology includes steps such as rhodium ore beneficiation, rhodium salt preparation, electrolytic rhodium salt solution, refining, etc.

1. Rhodium ore beneficiation: Rhodium ore mainly exists in platinum group element ores, such as rhodium sulfide ore, platinum rhodium ore, etc. The purpose of beneficiation is to improve the grade and recovery rate of rhodium ore through physical and chemical means. Mineral processing mainly includes steps such as ore crushing, crushing, screening, flotation, and gravity separation.

2. Preparation of rhodium salt: After beneficiation, the rhodium ore undergoes steps such as crushing, crushing, and leaching to obtain a rhodium containing solution. The solution contains Platinum group such as rhodium, rhodium and palladium, and impurities such as iron and nickel. In order to increase the content of rhodium, it is necessary to remove other metal ions. Usually, solvent extraction or ion exchange methods are used for purification. After purification, a solution containing rhodium is obtained, and then rhodium salt is prepared by adding chemical reagents.

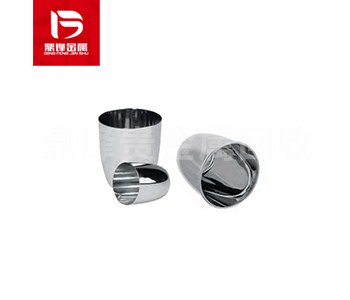

3. Electrolytic rhodium salt solution: Dissolve the rhodium salt in water to produce an electrolyte containing rhodium salt. Usually, anhydrous ammonia is used as a solvent for electrolysis in an ammonia atmosphere. Electrolytic electrodes usually use titanium mesh electrodes with a current density of 50-100A/dm2. During the electrolysis process, rhodium ions are oxidized to RuO4 on the anode and then reduced to rhodium on the cathode. The rhodium powder obtained by electrolysis can be dried, sintered, and other steps to obtain high-purity rhodium.

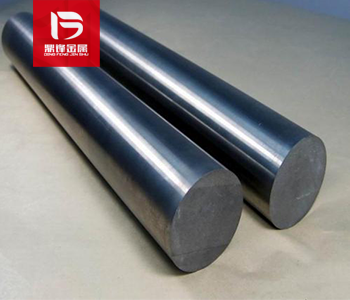

4. Rhodium refining: The rhodium obtained through electrolysis contains a small amount of impurity metal and needs further refining. Common refining methods include Vacuum distillation, lead oxide refining and smelting. Among them, the Vacuum distillation method is to heat the rhodium containing impurities to high temperature, evaporate the impurities, collect and remove them, and obtain high-purity rhodium. The lead oxide method involves heating rhodium containing impurities with lead oxide to oxidize the impurity metal into oxide, which is then adsorbed on the surface of lead oxide to obtain high-purity rhodium.

2、 Advantages and disadvantages

Advantages: (1) Low production cost: Compared to other methods of extracting rhodium, electrolytic rhodium technology has the advantage of low production cost, which can effectively improve the yield and economic benefits of rhodium. (2) High purity: Electrolytic rhodium technology can obtain high-purity rhodium, suitable for high-end applications such as electronics and medical devices.

Disadvantages: (1) Complex process: The process flow of electrolytic rhodium technology is relatively complex, requiring a lot of time and cost. (2) Environmental pollution: Electrolytic rhodium technology requires the use of chemical reagents, which can cause certain pollution to the environment, and environmental protection needs to be strengthened.

3、 Application situation

Rhodium has a wide range of applications in industrial production, mainly including catalysts, electrode materials, medical devices, and other fields.

1. Catalyst: Rhodium, as an excellent catalyst, has important applications in organic synthesis, automotive exhaust treatment, and other fields. Rhodium catalysts can catalyze reactions such as hydrogenation, oxygenation, and oxidation of organic compounds such as olefins and aromatics.

2. Electrode material: Rhodium is a metal with high conductivity and stability, which can be used to prepare high-performance electrode materials. For example, rhodium can be used in the production of Whitman cells, fuel cells, etc.

3. Medical devices: Rhodium is also widely used in the field of medical devices, such as prostheses and radiation therapy. The radioactive properties of rhodium can effectively kill cancer cells, thus being used for radiation therapy.

4、 Development Trends

With the continuous development of technology and the increasing demand for high-quality materials, the demand for rhodium is also increasing. Therefore, electrolytic rhodium technology has broad application prospects in the future.

1. Increase production capacity: The development of electrolytic rhodium technology requires improving production efficiency and capacity, reducing costs, and improving economic benefits.

2. Reducing pollution: The electrolytic rhodium technology needs to strengthen environmental protection, control the discharge of pollutants such as exhaust gas and wastewater, and reduce its impact on the environment.

3. Innovative materials: Electrolytic rhodium technology can provide high-purity and high-performance rhodium materials for the development of new materials, promoting the development and application of new materials.

4. Automated production: With the development of automation technology, electrolytic rhodium technology will also achieve automated production, improving production efficiency and quality.

Electrolytic rhodium technology is an important rhodium extraction technology with advantages such as low production cost and high purity, widely used in catalysts, electrode materials, medical devices, and other fields. With the continuous development of technology and the increasing demand for high-quality materials, electrolytic rhodium technology has broad application prospects in the future. At the same time, it is necessary to strengthen environmental protection, control the emission of pollutants such as exhaust gas and wastewater, and achieve the goal of sustainable development.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;