What is rhodium powder? Steps of Rhodium Powder Recovery and Extraction Method

1、 Introduction to Rhodium PowderRhodium is a rare precious metal element belonging to the platinum group. Rhodium powder refers to the powdery substance formed by crushing, grinding, and other treatm

1、 Introduction to Rhodium Powder

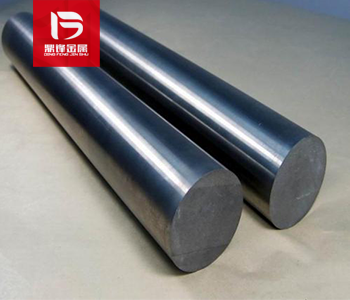

Rhodium is a rare precious metal element belonging to the platinum group. Rhodium powder refers to the powdery substance formed by crushing, grinding, and other treatments of rhodium elements. Rhodium powder has high melting point, high corrosion resistance, and excellent antioxidant performance, and is widely used in fields such as automotive exhaust catalysts, chemical industry catalysts, and the preparation of high-purity rhodium products.

2、 Rhodium powder source

There are two main sources of rhodium powder:

1. Natural resources: Rhodium metal is mainly present in platinum and nickel ores, usually coexisting with other platinum group elements. Due to the extremely low content of rhodium in the crust, the extraction and extraction costs of rhodium are relatively high.

2. Recycling source: With the advancement of technology and the enhancement of environmental awareness, more and more rhodium powder is obtained through recycling waste catalysts, electronic waste, and other means. This method not only reduces the demand for rhodium metal mining, but also reduces environmental pollution.

3、 Recovery and extraction methods of rhodium powder

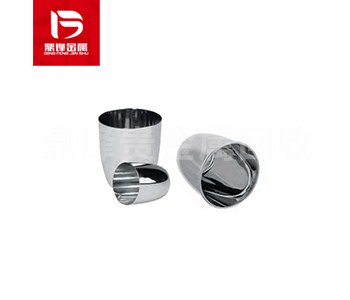

The recovery and extraction of rhodium powder mainly includes the following steps: 1. Pretreatment: Firstly, the waste catalyst and electronic waste are sorted and crushed to fully separate rhodium metal from other materials, preparing for the subsequent extraction of rhodium powder. 2. Chemical leaching: Soak the pretreated material in a specific chemical solvent, such as hydrochloric acid, nitric acid, etc. This process can separate rhodium metal from other impurities, forming a rhodium salt solution. 3. Chemical precipitation: add reducing agent, such as hydrogen or Sodium sulfite, to the rhodium salt solution to precipitate the rhodium metal. The precipitate contains high-purity rhodium metal. 4. Roasting reduction: Place the rhodium precipitate in a high-temperature furnace for roasting, separating it from other impurities, and reducing it to metallic rhodium. During the roasting reduction process, rhodium metal particles gradually aggregate to form granular substances. 5. Crushing and grinding: The rhodium particles after roasting and reduction are crushed and ground to form small powder like substances, namely rhodium powder. This process is usually achieved using equipment such as high-energy ball mills. 6. Classification and purification: Further purification and classification of rhodium powder are carried out through methods such as airflow classification and magnetic separation to meet the purity and particle size requirements of different application scenarios. 7. Packaging and storage: The purified rhodium powder is Vacuum packing and sealed to prevent it from being affected by air and moisture during storage and transportation, so as to ensure stable and reliable product quality.

Rhodium powder is a rare metal powder with broad application prospects, and its recovery and extraction methods balance environmental protection and economic benefits. Through multiple processes such as pretreatment, chemical leaching, chemical precipitation, roasting reduction, crushing and grinding, classification and purification, the recovery and extraction of rhodium metal have been successfully achieved. With the development of technology and the increasing demand for rare resources, the recovery and extraction technology of rhodium powder will continue to be optimized and upgraded to achieve more efficient, green, and sustainable resource utilization.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;