Rhodium rod recycling_ Specific process of recovering and refining rhodium rods using chemical precipitation method

The chemical precipitation method involves converting rhodium ions from rhodium containing waste into precipitates, and then purifying rhodium through steps such as filtration, washing, and drying. Th

The chemical precipitation method involves converting rhodium ions from rhodium containing waste into precipitates, and then purifying rhodium through steps such as filtration, washing, and drying. This method is simple to operate, relatively low in cost, and suitable for recycling waste with low rhodium content. The following will provide a detailed introduction to the specific steps of chemical precipitation method for recovering rhodium rods.

The specific process of recovering rhodium rods by chemical precipitation method

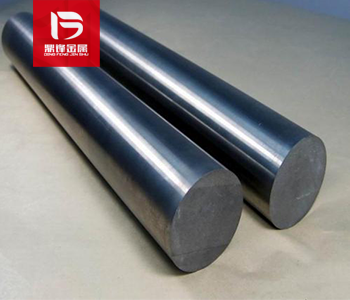

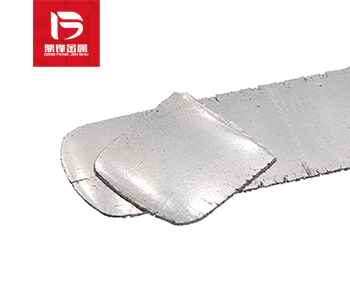

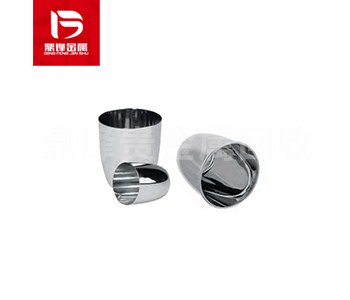

1. Waste pre-treatment: The collected rhodium containing waste first needs to undergo pre-treatment such as classification, crushing, and screening to remove impurities, increase rhodium content, and create conditions for subsequent extraction of rhodium. 2. Acid leaching process: Soak the pre-treated waste in an acidic solution, such as hydrochloric acid, nitric acid, etc., to dissolve the rhodium ions in it. Factors such as acid leaching time, temperature, and acid concentration can all affect the leaching effect of rhodium. After the acid leaching process is completed, the waste residue is filtered and removed, leaving a rhodium containing solution. 3. Precipitation process: add an appropriate amount of reducing agent, such as Sodium nitrite, Sodium thiosulfate, etc. to the rhodium containing solution. These reducing agents will reduce rhodium ions to metal rhodium precipitates. During this process, attention should be paid to controlling reaction conditions, such as solution pH, temperature, etc., to ensure the purity and yield of the precipitate. 4. Filtration, washing, and drying: The generated metal rhodium precipitate is separated by filtration, and then washed with distilled water or dilute acid to remove residual impurities and reducing agents. The rhodium precipitate after washing needs to be dried, usually using methods such as a drying oven or vacuum drying. 5. Rhodium powder purification: The dried rhodium powder may still contain a certain amount of impurities and further purification is needed. The commonly used purification methods include fire purification and wet purification. Fire purification involves melting rhodium powder at high temperatures to separate impurities. Wet purification involves dissolving and precipitating rhodium powder again, and improving purity through multiple repeated operations. 6. Rhodium preparation: The purified rhodium powder can be used to prepare new rhodium rods or other rhodium products. Rhodium rods are usually prepared by powder metallurgy, which involves pressing rhodium powder into shape and then sintering at high temperatures. The resulting rhodium rod has high purity and good performance.

Advantages and disadvantages of chemical precipitation method for recovering rhodium rods

Advantages:

1. Simple operation: The operation process of the chemical precipitation method is relatively simple and does not require complex equipment or high skill operations. 2. Lower cost: Compared to other extraction methods, the chemical precipitation method has a lower cost, which helps to reduce the total cost of rhodium rod recovery. 3. Wide application range: The chemical precipitation method is suitable for recycling waste with low rhodium content and has a wide range of applicability.

Disadvantages:

1. Limited recovery efficiency: The chemical precipitation method is affected by the waste composition, resulting in limited recovery efficiency and may not be able to fully recover rhodium. 2. Possible environmental pollution: During acid leaching, sedimentation, and other processes, pollutants such as wastewater and exhaust gas may be generated. Therefore, corresponding environmental protection measures need to be taken to reduce the impact on the environment.

The chemical precipitation method, as a rhodium rod recovery method, has the advantages of simple operation and low cost. However, its recycling efficiency is affected by the composition of waste, which may cause environmental pollution. Therefore, in practical operation, it is necessary to select appropriate recycling methods based on specific circumstances to achieve efficient and environmentally friendly recycling of rhodium resources. At the same time, increase research investment, optimize recycling technology, improve the efficiency of rhodium rod recycling, and contribute to the sustainable development of the global resource recycling economy.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;