Palladium carbon recovery_ Recovery of Palladium from Waste Palladium on carbon

Palladium is a precious metal that is highly valued for its unique properties, including corrosion resistance, ductility, and high conductivity. It is widely used in many industries, including electro

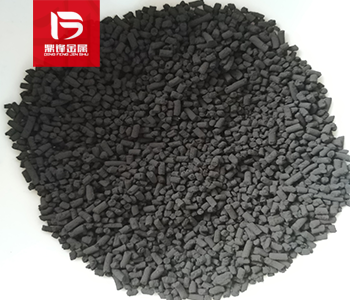

Palladium is a precious metal that is highly valued for its unique properties, including corrosion resistance, ductility, and high conductivity. It is widely used in many industries, including electronics, automobiles, and pharmaceuticals. Palladium carbon catalysts are commonly used catalysts in organic synthesis reactions. Unfortunately, these catalysts will eventually decompose and require replacement, resulting in significant waste. Due to the high cost of palladium and the impact of waste materials on the environment, the recovery of palladium from waste Palladium on carbon has aroused great interest. This article will explore different methods for recovering palladium from waste palladium carbon catalysts.

Recovery method of waste Palladium on carbon:

Chemical methods. There are several different chemical methods for recovering palladium from waste palladium carbon catalysts. One of the most common methods is leaching, which involves dissolving palladium in the catalyst in a suitable solvent. Then treat the solution with a reducing agent to precipitate the metal palladium. Usually, hydrochloric acid or nitric acid is used for acid leaching. Ammonium chloride can be added to the solution to improve extraction efficiency. However, this method requires careful control of the pH value of the solution to avoid the formation of insoluble palladium salts.

Another chemical method is precipitation. Precipitation is the addition of a reagent to a solution to precipitate palladium in solid form from the solution. The most commonly used reagents in this method are Sodium borohydride, Sodium formate and sodium hydroxide. The generated solid is then filtered, washed, and dried. Although precipitation method is an effective method, it often produces impure palladium, which may require further refinement.

Electrochemical method. Electrochemical method is a commonly used method for recovering palladium from waste palladium carbon catalysts. The electrochemical method includes Palladium(II) oxide oxidation by transferring current through the catalyst. This method is more effective than chemical methods because it avoids the formation of palladium salts. One electrochemical method is electrolysis, which involves electrolysis of an aqueous solution of palladium salts using a palladium electrode. Palladium ions are reduced to solid palladium on the electrode. This method can recover high-purity palladium and can be expanded to industrial use. Another electrochemical method is electrowinning, which involves electrolysis of palladium salt aqueous solutions using non palladium electrodes. On the cathode, palladium ions are reduced to solid palladium. This method consumes less energy than electrolysis and can also obtain high-purity palladium.

Fire metallurgy method. The pyrometallurgical method includes heating the spent catalyst to high temperature to recover palladium. One such method is smelting, which involves melting spent catalysts and reducing agents (such as coke or charcoal) to produce slag containing impurities and metal palladium buttons. Then, chemical or electrochemical methods are used to further refine the metal buttons. Another fire method is roasting. In this method, the waste catalyst is oxidized at high temperature, converting palladium into a soluble form. The generated solution can be treated by chemical or electrochemical methods to recover palladium.

Recovering palladium from waste palladium carbon catalysts has both economic and environmental benefits. Although there are several methods available, each method has its advantages and disadvantages, and the best method depends on the specific catalyst and desired results. Chemical methods such as leaching and precipitation are effective, but may produce impure palladium. Electrochemical methods such as electrolysis and electrowinning can obtain high-purity palladium, but require energy and specialized equipment. Fire metallurgical methods, such as smelting and roasting, require higher temperatures but can produce high yields of palladium metal. With the continuous growth of demand for palladium, it will become more and more important to recover palladium from waste Palladium on carbon.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;