Rhodium carbon recovery_ Describe the impact of recovering rhodium carbon from various aspects

Rhodium is one of the rarest and most valuable precious metals in the world. It is one of the Platinum group and is famous for its extremely high durability, excellent conductivity and corrosion resis

Rhodium is one of the rarest and most valuable precious metals in the world. It is one of the Platinum group and is famous for its extremely high durability, excellent conductivity and corrosion resistance. Rhodium odium is used in various applications, including catalysts in the automotive industry, electronic manufacturing, and jewelry manufacturing. As the demand for rhodium continues to increase, the demand for efficient and cost-effective recovery and recycling methods has become crucial. In this article, we will discuss the process of rhodium carbon recovery, its benefits, and its environmental impact.

What is rhodium carbon recycling?

Rhodium carbon recovery, also known as carbon treatment to recover rhodium, is a technology for extracting rhodium from waste catalysts. This process involves heating the spent catalyst with carbon at high temperatures in the presence of oxygen. This will cause rhodium to form a volatile compound that can be collected and processed to produce pure metal rhodium. This process starts with collecting spent catalysts. These catalysts are typically obtained from the automotive industry to reduce harmful emissions from vehicles. Waste catalysts contain trace amounts of precious metals, including rhodium that can be extracted and recovered. After collecting the catalysts, they are crushed and mixed with carbon, usually in the form of charcoal or graphite powder. Then heat the mixture of catalyst and carbon to a high temperature, usually between 800-1000 degrees Celsius. This will cause rhodium to form a volatile compound that can be collected and further processed to extract pure rhodium. The remaining carbon is often reused in subsequent batches of recycling, making this process more cost-effective.

Benefits of Rhodium Carbon Recovery

Compared to traditional mining and refining methods, rhodium carbon recovery has several benefits. One of the main benefits is the protection of natural resources. Rhodium is an extremely rare and valuable metal with limited reserves worldwide. By recycling rhodium from spent catalysts, we can reduce the overall demand for newly extracted rhodium, which can help conserve natural resources and minimize the environmental impact of mining activities. Another benefit of recovering rhodium carbon is that it provides a more cost-effective way to obtain rhodium. Traditional mining and refining methods may be expensive and require a significant amount of energy and resources. In contrast, the process of using carbon treatment to recover rhodium is relatively simple, requiring minimal equipment and infrastructure investment. This makes it a more affordable and accessible choice for businesses and organizations, as their business requires rhodium. From the perspective of environmental sustainability, the recovery of rhodium carbon catalysts also has benefits. Traditional mining and refining methods may have significant environmental impacts, including soil erosion, water pollution, and deforestation. By recycling rhodium from spent catalysts, we can reduce the demand for new mining activities and minimize the overall impact of extracting rhodium on the environment.

The impact of rhodium carbon recycling on the environment

Although rhodium carbon recycling provides many benefits, it is not without environmental impact. One of the main issues is the release of greenhouse gases during the process of recovering rhodium. This process involves heating the spent catalyst with carbon, which releases carbon dioxide and other greenhouse gases into the atmosphere. However, compared to traditional mining activities, the overall impact of these emissions is relatively small, and measures can be taken to reduce emissions. Another concern is that waste catalysts themselves may cause environmental pollution. Waste catalysts may contain trace amounts of harmful substances, including heavy metals and chemicals, which may be toxic to plants, animals, and humans. It is necessary to handle and dispose of waste catalysts carefully to minimize the risk of environmental pollution.

Rhodium carbon recovery provides a valuable solution for extracting and recovering rhodium from spent catalysts. This process is relatively simple and cost-effective, providing several benefits compared to traditional mining and refining methods, including protecting natural resources and environmental sustainability. Although environmental impacts need to be considered, the overall impact of recovering rhodium carbon is relatively small compared to traditional mining activities. With the continuous increase in demand for rhodium, the use of rhodium carbon recovery may become more critical in the coming years.

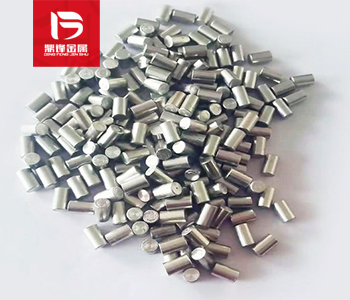

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;