Rhodium slurry recovery_ Uncovering the Hidden Value of Recycling Rhodium Slurry Waste

Rhodium is a rare and valuable transition metal mainly used in catalytic converters of automobiles. Its ability to reduce harmful emissions makes it a key element in the automotive industry. However,

Rhodium is a rare and valuable transition metal mainly used in catalytic converters of automobiles. Its ability to reduce harmful emissions makes it a key element in the automotive industry. However, rhodium is an extremely scarce resource, with only about 23.8 tons produced globally annually. High demand and limited supply have pushed the price of rhodium to a historic high, reaching over $28000 per ounce by the end of 2020. Given the high value of rhodium, it is surprising that the rhodium paste waste generated during the production of rhodium plating catalysts is often discarded as hazardous waste. These waste materials contain a large amount of valuable rhodium, which can be recycled through various recycling methods. Discovering the hidden value of rhodium slurry waste not only benefits the environment, but also provides manufacturers with a valuable opportunity to reduce production costs and generate additional income. The composition of rhodium slurry waste is usually composed of rhodium, platinum, Pd and other materials, such as glass, graphite and carbon. According to the specific manufacturing process, the rhodium content in the waste can range from 1% to 30%. The high content of rhodium in waste materials makes it an attractive source of recycling. There are various methods for recovering rhodium from rhodium slurry waste, including chemical, physical, and thermal methods. A widely used technique is hydrometallurgy, which involves dissolving rhodium paste waste in an acidic solution and then using a reducing agent to precipitate rhodium. Other technologies, such as pyrometallurgy and plasma treatment, have also shown promising results in extracting rhodium from waste.

Recycling rhodium from rhodium slurry waste not only provides a valuable source of metal, but also has significant environmental benefits. The recycling and utilization of these materials reduces the amount of waste entering landfills, saves natural resources, reduces energy consumption, and helps reduce the environmental impact of mining and refining. In addition, recycling rhodium from rhodium slurry waste can also save manufacturers significant costs. The high cost of rhodium may account for a significant portion of catalyst production costs.

By recycling rhodium from waste materials, manufacturers can significantly reduce material costs, improve production process efficiency, and improve their profits. In addition to cost savings, the recycling and utilization of rhodium slurry waste can also bring new business opportunities. As the demand for sustainable practices continues to increase, companies can promote their use of recycled materials as selling points to environmentally conscious consumers. Recycling Luo paste waste can also bring new sources of revenue to manufacturers, who can sell recycled metals. In recent years, efforts have been made to increase the recycling and utilization of rhodium slurry waste. However, the existing infrastructure for rhodium recycling cannot keep up with demand. Addressing these challenges requires increased investment in research and development, as well as cooperation among various stakeholders in the industry.

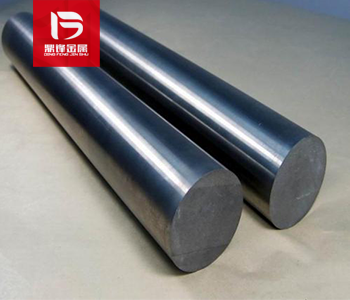

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;