Palladium mud recovery_ Palladium Anode Mud Recovery: Gospel for Industrial Applications

Due to the increasing demand for precious metals in various industries, recycling palladium anode slime has become a boon for industrial applications. Palladium (PD) is a precious metal mainly used in

Due to the increasing demand for precious metals in various industries, recycling palladium anode slime has become a boon for industrial applications. Palladium (PD) is a precious metal mainly used in the manufacturing of automotive catalytic converters, electronic products, and jewelry. It is one of the rarest metals in the world, and its mining and extraction processes are complex, time-consuming, and costly. Therefore, in order to meet the high demand for palladium, recovered palladium anode slime has been introduced as an alternative source. This article discusses the importance of palladium anode slime recovery and its application in various industries.

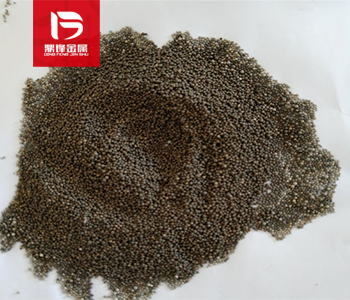

Palladium anode slime is a byproduct of the electrolytic refining process of copper, nickel, and other base metals. Anode mud contains various precious metals, such as palladium, platinum, gold, silver, and other base metals. Therefore, it is considered a secondary source of precious metals. In the past, anode slime was discarded as waste, but with the increasing demand for precious metals, recycling these metals from anode slime has become a profitable business in the recycling industry.

Palladium is commonly used in the automotive industry to manufacture catalytic converters to reduce harmful emissions from vehicles. The catalytic converter adopts a honeycomb structure of platinum and palladium, with a large amount of palladium used in each converter. According to a report by leading catalytic converter manufacturer Johnson Mattel, the average palladium content of each catalytic converter is approximately 0.25 grams. With the production of millions of cars every year, the demand for palladium is soaring, making the recycling of palladium anode slime an essential process.

In addition to the automotive industry, the electronics industry is another industry heavily reliant on palladium. Palladium is widely used to manufacture multilayer Ceramic capacitor (MLCC), which are basic components of electronic devices such as smart phones, computers and tablets. MLCC stores, filters, and regulates electrical signals in electronic devices. With the increasing use of electronic devices, the demand for palladium in the electronics industry is also constantly increasing. Therefore, in order to meet the demand for precious metals in the electronics industry, the palladium anode slime recovery process has become crucial.

The recovery of palladium anode slime involves several steps, including leaching, precipitation, and refining. The first step is to leach the anode mud, which involves dissolving the metal in an acidic solution. The acidic solution dissolved base metals such as copper and nickel, leaving behind precious metals including palladium. The second step is precipitation, which separates palladium from the solution by adding a reducing agent. This reducing agent reduces palladium ions in the solution to palladium metal, which is then collected through filtration. The third step is refining, which involves purifying palladium metal through various processes such as smelting, electrorefining, and chemical treatment. Recycling palladium anode slime has several benefits for different industries. Firstly, it reduces dependence on the main sources of precious metals, as precious metal resources are limited and expensive. Secondly, this is a sustainable way to obtain precious metals, as anode slime is a by-product of recycling from other metal refining processes. Thirdly, it reduces the environmental impact of metal refineries, as the treatment of anode sludge previously caused pollution and waste.

Due to the increasing demand for precious metals in various industries, recycling palladium anode slime has become a boon for industrial applications. Recycling palladium anode slime provides a sustainable and cost-effective way to obtain precious metals, thereby reducing dependence on primary sources of precious metals. Industries such as automobiles, electronics, and jewelry can benefit from the palladium anode slime recycling process as it provides a reliable source of palladium for manufacturing. Overall, the palladium anode slime recovery process is a key solution to meet the growing demand for precious metals and create a more sustainable future.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;