Palladium carbon recovery_ Sustainable Recovery of Palladium from Industrial Palladium on carbon

Palladium (Pd) is a rare metal widely used in various industrial applications, including automotive catalytic converters, electronics, and chemical synthesis. It is a valuable metal due to its unique

Palladium (Pd) is a rare metal widely used in various industrial applications, including automotive catalytic converters, electronics, and chemical synthesis. It is a valuable metal due to its unique chemical and physical properties, including strong corrosion resistance and oxidation resistance, high catalytic activity, and excellent conductivity. However, like many rare metals, the supply of palladium is limited, and its extraction may damage the environment. Therefore, the sustainable recovery of palladium is of great significance for both industry and the environment.

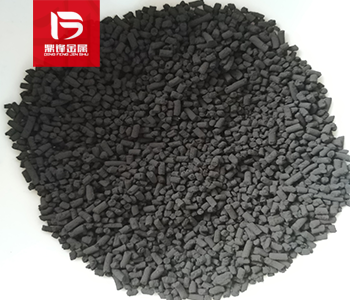

One of the most common sources of palladium is industrial palladium carbon catalysts, which are widely used in the chemical industry. These catalysts are made by impregnating activated carbon with palladium ions, and then reducing them to metallic palladium using reducing agents such as hydrogen. The palladium carbon catalysts obtained from this are very effective in catalyzing a wide range of chemical reactions, but they also contain a large amount of valuable palladium that can be recovered. There are several methods for recovering palladium from industrial palladium carbon catalysts, each with its own advantages and disadvantages. One of the most common methods is acid leaching, which involves dissolving the catalyst in acid to remove palladium. This method is effective, but it may damage the environment as it releases toxic gases such as sulfur dioxide.

Sustainable palladium recovery methods.

1. A more sustainable method for palladium recovery is to use ion exchange resins. Ion exchange resin is a highly porous material that can selectively adsorb metal ions in solution. In this method, the palladium carbon catalyst is first crushed into powder and then leached with a suitable solvent to remove palladium. Then, the generated solution selectively adsorbs palladium ions through an ion exchange resin column. Once palladium ions are adsorbed onto ion exchange resins, they can be eluted with suitable eluents such as hydrochloric acid. The generated palladium solution can then be further processed to obtain pure palladium metal. This method has several advantages compared to acid leaching, including less impact on the environment and higher selectivity for palladium ions.

2. Another sustainable method for recovering palladium is hydrometallurgical recovery. This method involves dissolving the palladium carbon catalyst in a suitable solvent, usually nitric acid, and then selectively precipitating palladium ions using a reducing agent such as Sodium borohydride. The resulting palladium powder can be further processed to obtain pure palladium metal. Compared to traditional palladium recovery methods, hydrometallurgical recovery has several advantages. Firstly, it is more environmentally friendly as it does not involve the use of toxic acids or other hazardous chemicals. In addition, hydrometallurgical recovery has high selectivity for palladium and can recover high-purity palladium with minimal pollution to other metals.

3. In addition to these methods, there are several emerging technologies for sustainable palladium recovery. One of the technologies is the selective leaching of palladium from industrial wastewater using bacteria. Thiobacillus Iron(II) oxide and other bacteria can oxidize sulfides in industrial wastewater, producing an acidic environment that can dissolve palladium and other metals. This method has the potential to selectively recover palladium from waste streams very effectively while minimizing its impact on the environment.

4. Another emerging technology is the use of renewable energy sources such as solar energy to drive the recovery process of palladium. Solar electrochemical recovery has the potential for high sustainability as it uses renewable energy and does not require the use of hazardous chemicals. In addition, this technology has the potential for highly selective recovery of palladium, reducing the amount of waste generated during the process.

Overall, the sustainable recovery of palladium from industrial palladium carbon catalysts is an important issue for both industry and the environment. Although traditional methods such as acid leaching are effective, they may also damage the environment. The use of more sustainable methods such as ion exchange resins and hydrometallurgical recovery, as well as emerging technologies such as bacterial leaching and solar electrochemical recovery, provide promising alternative solutions that can reduce environmental impacts while recovering valuable palladium resources. As the demand for palladium continues to grow, sustainable recycling methods will become increasingly important for the long-term viability of the industry.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;