Palladium graphite recovery_ A Method for Recovering Palladium from Waste Palladium Graphite Catalysts

Palladium graphite catalysts are widely used in crude oil refining and chemical production. However, after a certain period of use, the palladium component in the catalyst will gradually lose, thereby

Palladium graphite catalysts are widely used in crude oil refining and chemical production. However, after a certain period of use, the palladium component in the catalyst will gradually lose, thereby reducing the catalytic activity of the catalyst and affecting the quality of the final product. Therefore, recovering palladium from waste palladium graphite catalysts has become an important aspect of resource conservation and environmental protection. This article introduces several methods for recovering palladium from waste palladium graphite catalysts.

Method for recovering palladium using palladium graphite catalyst:

1. Acid leaching precipitation method.

The acid leaching precipitation method is a simple and widely used method for recovering palladium from palladium graphite catalysts. The main principle of this method is to dissolve palladium from waste catalyst through acid leaching, and then precipitate palladium from solution through reduction or Single displacement reaction. Generally, hydrochloric acid or nitric acid is used as leaching agent, and hydrazine or Sodium borohydride and other reducing agents are used for palladium precipitation.

The process of acid leaching precipitation method is as follows:

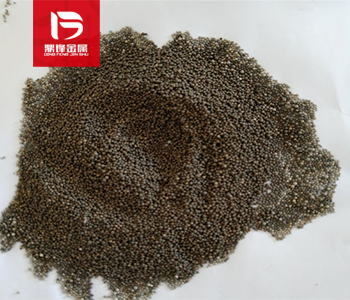

1. Crush and grind the used palladium graphite catalyst into powder.

2. Then mix the powder with an acidic solution (5-10% HCl or 5-10% HNO3) in a reactor.

3. Heat the mixture and stir for several hours to dissolve palladium from the catalyst.

4. After leaching, the filtrate removes insoluble residues.

5. Then add a reducing agent, such as hydrazine or Sodium borohydride, to reduce or replace palladium in the solution.

6. The reduced or replaced palladium precipitates in the form of solid palladium powder.

7. Wash palladium powder with distilled water and dry at high temperature to obtain high-purity palladium.

This method has the advantages of low cost, simple operation, and good recovery rate. However, there are also limitations such as high acid consumption, long leaching time, and difficult to control reaction conditions.

2. Alkali melting method.

Alkali melting method is another effective method for recovering palladium from waste palladium graphite catalysts. The principle of this method is to dissolve the palladium component in the catalyst by melting it with sodium hydroxide or potassium hydroxide, and then extract palladium from the melt by acid leaching or precipitation with reducing agent.

The process flow of alkali melting method is as follows:

1. Crush and grind the used palladium graphite catalyst into powder.

2. The powder is mixed with sodium hydroxide or potassium hydroxide in a reactor.

3. Heat the mixture and stir for several hours until the palladium component completely melts.

4. Cool the molten mixture and dissolve it in water.

5. Extract palladium from the solution using acid leaching method or add reducing agents for precipitation.

6. Wash palladium powder with distilled water and dry at high temperature to obtain high-purity palladium.

The advantage of this method is that it can effectively dissolve the palladium component in the waste catalyst, and the purity of the recovered palladium is very high. However, it also has drawbacks such as high cost, complex operation, and environmental pollution caused by the use of strong alkali.

3. Heat treatment method.

The heat treatment method is a green and low-cost method for recovering palladium from waste palladium graphite catalysts. The principle of this method is to heat the used catalyst at high temperature, decompose the graphite matrix, release palladium components, and then recover palladium from the product through physical or chemical methods.

The process of heat treatment method is as follows:

1. Heat the used palladium graphite catalyst in a high-temperature (800-1000 ℃) furnace for several hours.

2. The graphite matrix in the catalyst decomposes and the palladium component is released.

3. Then wash the product with acid to remove impurities.

4. Palladium in products can be recovered through physical methods such as filtration or magnetic separation, as well as chemical methods such as leaching or precipitation.

5. Wash palladium powder with distilled water and dry at high temperature to obtain high-purity palladium.

This method has the advantages of low cost, green environmental protection, and high recovery rate. However, there are also some limitations, such as long heating time and low concentration of palladium components in old catalysts, which may affect the recovery rate of palladium.

4. Bioleaching method.

Bioleaching is a new method to recover palladium from waste palladium graphite catalyst, which has broad application prospects. The principle of this method is to selectively dissolve the palladium component in the spent catalyst using bacteria or fungi, and then extract palladium from the resulting solution through precipitation or electrodeposition.

The process flow of Bioleaching method is as follows:

1. Crush and grind the used palladium graphite catalyst into powder.

2. Mix the powder with a bacterial or fungal solution in a reactor.

3. Stir and incubate the mixture for a few days to dissolve palladium from the catalyst.

4. Filter the generated solution to remove insoluble residues.

5. Use precipitation or electrodeposition to recover palladium from the solution.

6. Wash palladium powder with distilled water and dry at high temperature to obtain high-purity palladium.

This method has the advantages of low cost, environmental friendliness, and high recovery rate. However, it also has some limitations, such as low selectivity of bacterial or fungal activity and difficulty in controlling reaction conditions.

The recovery of palladium from used palladium graphite catalysts is a complex process that requires careful selection of recovery methods based on the specific situation of the used catalyst. Among various methods, acid leaching precipitation method and alkali melting method are widely used because of their high recovery rate and good purity, while heat treatment method and Bioleaching method are emerging green and low-cost methods with great development potential. In order to achieve efficient and sustainable palladium recovery, it is necessary to continue improving existing methods and exploring new technologies.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;