Platinum rhodium leakage plate recycling_ What is the platinum rhodium alloy leakage plate? The Use of Platinum Rhodium Leakage Plate

What is the platinum rhodium alloy leakage plate?Platinum rhodium alloy leakage plate, abbreviated as platinum rhodium leakage plate, is a type of platinum rhodium secondary alloy product with platinu

What is the platinum rhodium alloy leakage plate?

Platinum rhodium alloy leakage plate, abbreviated as platinum rhodium leakage plate, is a type of platinum rhodium secondary alloy product with platinum rhodium wire. Platinum rhodium alloy leakage plate is an alloy material composed of platinum as the main material, and a small amount of rhodium is added together. Rhodium is re added to platinum, mainly to further enhance the plastic resistance during the adoption process, and to further enhance the service life and performance stability of the leakage plate. For example, it can make the leakage plate stable, difficult to deform, more resistant to the erosion of high-temperature glass liquid, and more difficult to rust in medium to long-term high-temperature production. To understand that the working temperature of platinum rhodium leakage plates can reach up to 1300C, it requires a lot of dynamic and static pressure to withstand.

The purpose of platinum rhodium alloy leakage plate:

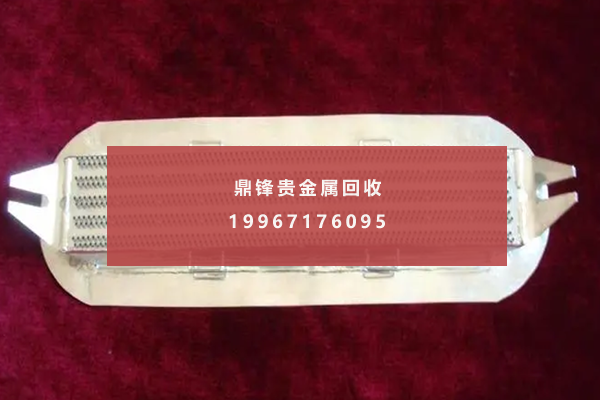

Platinum rhodium alloy leakage plates can be mainly used in the glass fiber industry and are also known as the heart of the glass fiber drawing process. Whether the platinum rhodium leakage plate is in good condition directly determines whether the glass fiber production can meet the required requirements. Platinum rhodium leakage plates can be divided into crucible leakage plates and tank kiln leakage plates according to the type of use: the number of low plate holes in crucible leakage plates ranges from 100 to 800, and the number of low plate holes in tank kiln leakage plates ranges from 800 to 8000, and the content is also not uniform. The content of small leakage plates is generally around 10%. The different contents of pores also vary. The larger the hole, the higher the content. The leakage plate is one of the temperature control devices used in the micro heating process of glass fiber production, and its shape is a U-shaped container groove. The temperature of the leakage plate is generally around 1300 degrees, and the platinum rhodium leakage plate itself can generate heat and adjust temperature, becoming an indispensable component of the wire drawing process. Platinum rhodium leakage plate is the most perfect process for glass fiber drawing.

During the use of the leakage plate, it is recommended that the skills of the operating personnel are relatively high. During the use of the leakage plate, it is unfolded under harsh high temperatures, and the operating experience of the operating personnel is the key to the use cycle of the leakage plate. It is difficult for the leakage plate to deform and fall off during long-term operation, and foreign objects falling down during the production process can cause the reaction of the platinum rhodium leakage plate to be interrupted. When in use, the electrode edge is burned, resulting in breakage. Platinum rhodium welding technology for electric leakage plates is also crucial. Problems such as stamping bubbles, welding slag, and undercutting can also lead to poor working conditions and reduced strength of the rhodium plate, affecting its overall service life. During the production of leakage plates, glass fiber additives will also produce chemical reactions on the leakage plates. The temperature control of the leakage plate is a clear indicator of overall success or failure. If the temperature of the internal network of the leakage plate is too high and heated privately, it will cause deformation and detachment of the welding joint of the leakage plate. The frequency of changing leakage plates is very high. Generally speaking, companies frequently change leakage plates to improve productivity, ensure product quality, and enhance enterprise efficiency. The service life of platinum rhodium leakage plates is usually 12 months.

The recycling and purification method of waste platinum rhodium leakage plates: During the production process of enterprises, a large number of leakage plates are replaced, and enterprises can choose to recycle and dispose of waste leakage plates, which can be recycled. The leakage plate contains platinum and rhodium elements, which can be purified and separated. Recycling once again ensures the production rate of the enterprise and is in line with sustainable recycling development. The recycling of platinum rhodium leakage plates usually involves replacement, undercutting, breakage, severe deformation, blockage of leakage plate holes, and electrode damage.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;