Rhodium slag recovery_ What are the factors that affect rhodium extraction in rhodium slag recovery

What is rhodium residue?Rhodium is a rare silver white metal widely used in various applications, including automotive catalytic converters, electrical and electronic equipment, and jewelry. Due to it

What is rhodium residue?

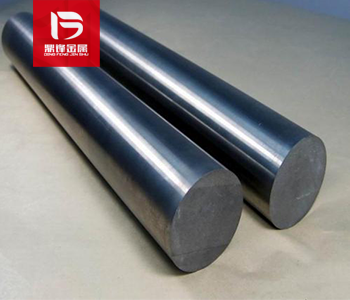

Rhodium is a rare silver white metal widely used in various applications, including automotive catalytic converters, electrical and electronic equipment, and jewelry. Due to its widespread use, a large amount of rhodium slag is generated in industrial processes. For economic and environmental reasons, extracting rhodium from these residues has become increasingly important.

What are the extraction methods and influencing factors of rhodium residue?

Extracting rhodium from residues can be achieved through various methods, including pyrometallurgical and hydrometallurgical techniques. Fire metallurgy technology, such as smelting and refining, involves the use of high temperature to extract rhodium from residues. This method is typically used to treat advanced residues, such as those generated by catalytic converters. On the other hand, hydrometallurgical technology involves the use of chemical reactions to extract rhodium from residues. This method is typically used to treat low-grade residues, such as those generated by electronic and electrical equipment. The most common hydrometallurgical technique used for extracting rhodium is leaching, which involves the use of suitable leaching agents to dissolve rhodium from the residue.

The selection of rhodium extraction methods depends on several factors, including the composition of the residue, the required purity for extracting rhodium, and the cost of the extraction process. Generally speaking, pyrometallurgical technology has higher costs but produces higher purity rhodium, while hydrometallurgical technology has lower costs but produces lower purity rhodium. After extraction, rhodium is usually purified using various methods, including electrolysis, distillation, and precipitation.

The purity of rhodium is crucial for its intended use, and the required level of purity may vary depending on the application. For example, rhodium used in catalytic converters must have high purity, while rhodium used in jewelry may require lower purity levels. Extracting rhodium from residues is an important component of the metal refining industry as it provides a source of high-quality rhodium for various applications. In addition, extracting rhodium from residues helps reduce waste and prevent environmental pollution, as if not properly treated, residues often pose a threat to the environment. Extracting rhodium from residues is a key part of the metal refining industry. The choice of extraction method depends on several factors, including the composition of the residue, the required purity for extracting rhodium, and the cost of the extraction process. Extracting rhodium from residues provides a source of high-quality rhodium for various applications, while also helping to reduce waste and prevent environmental pollution.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;