Palladium recovery_ Method for recovering and refining palladium from palladium ore or palladium waste

There are various sources of palladium waste, mainly including the following:1. Industrial waste: This is the most common source of palladium waste, including waste generated in the production process

There are various sources of palladium waste, mainly including the following:

1. Industrial waste: This is the most common source of palladium waste, including waste generated in the production process of electronic products, auto parts, oil refineries, etc.

2. Medical waste: Palladium containing waste generated from medical devices, radioactive materials, etc.

3. Old metal products: Old metal products, old electronic products, etc.

4. Polluted soil and wastewater: Due to industrial pollution, soil and wastewater may contain palladium metals.

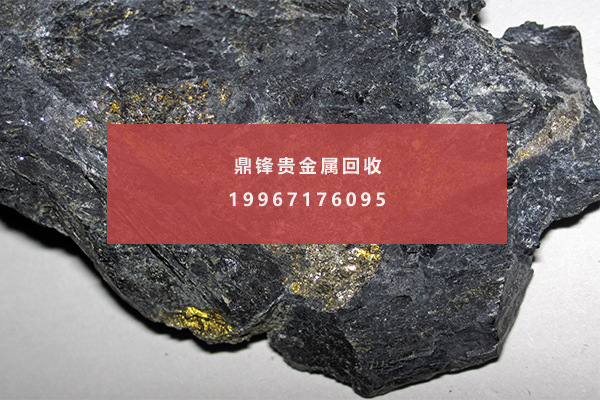

5. Mining waste: Mining waste refers to the remaining waste after extracting palladium metal from palladium ore.

Palladium extraction refers to the process of extracting palladium metal from palladium ore or palladium waste. There are several common methods for extracting palladium:

1. Sulfuric acid leaching method: Palladium ore or palladium waste is added to a sulfuric acid solution to separate palladium metal from other metals.

2. Electrolysis method: Palladium ore or palladium waste is placed in an electrolytic cell and current is used to separate palladium metal from other metals.

3. Melting method: Palladium ore or palladium waste is added to a high-temperature melting furnace to separate palladium metal from other metals.

4. Dissolution method: Palladium ore or palladium waste is added to a specialized dissolution solution to separate palladium metal from other metals.

Below, let's briefly explain the steps of extracting metals using sulfuric acid leaching method from Dingfeng Precious Metal Recycling:

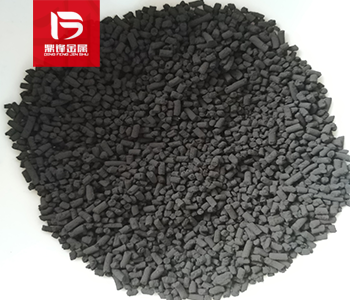

1. Preparation: Decompose palladium waste into as small powder or fragments as possible for better extraction of palladium.

2. Alkaline leaching: put the powder or fragment into the container containing alkaline solution (such as sodium sulfate or Sodium nitrate) to separate palladium from other metals.

3. Recrystallization: Crystallization of palladium metal from the solution, followed by cooling and drying treatment.

4. Filtration: Filter the remaining substance in the solution and cool it again to ensure complete crystallization of palladium metal.

5. Refining: Refining the filtered palladium metal to obtain high-purity palladium.

Please note that extracting palladium metal is a toxic and dangerous process that should be carried out by professionals under safe conditions. The above methods are only a simple theoretical reference statement, and we are not responsible for any inaccuracies.

&Quot; Dingfeng Precious Metals Recycling includes precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium, etc. This is our business in precious metal recycling. If you have precious metals such as gold, silver, palladium, rhodium, platinum, germanium, iridium, ruthenium that need to be recycled, please contact us and we will provide you with a satisfactory price& Quot;